Terram Geocell

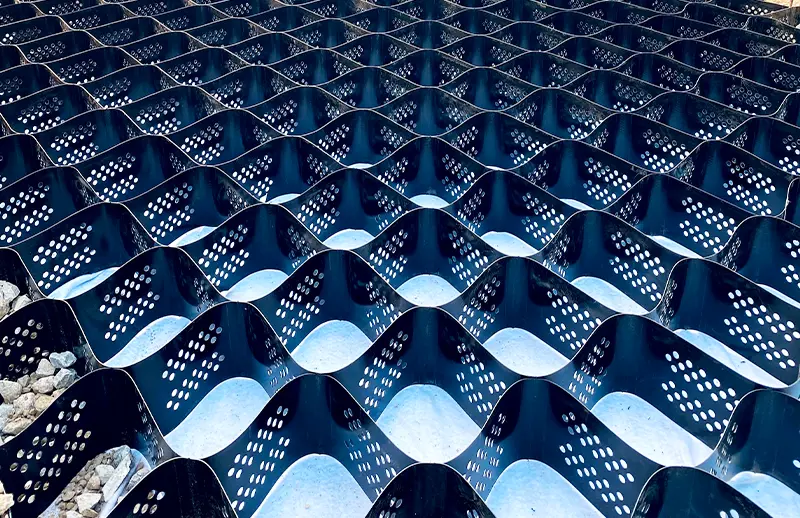

Material: High-Density Polyethylene (HDPE)

Key Properties: Excellent tensile strength, puncture resistance, UV stability, and resistance to biological degradation.

Seam Strength: Ultrasonically welded seams ensure uniform, high-strength cell interconnectivity.

Dimensions: Available in various cell depths, seam spacings, and sheet sizes to meet specific project design requirements.

Terram Geocell

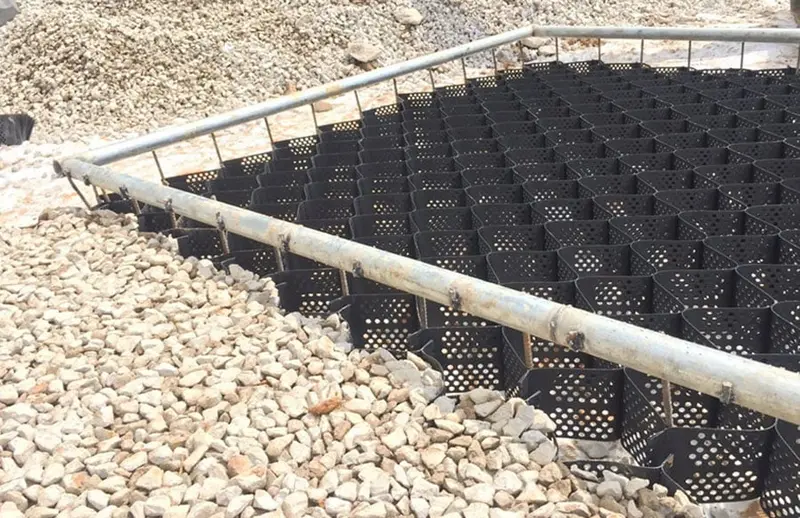

Geocell is three dimensional, honeycomb like structures manufactured from high density polyethylene and jointly welded by ultrasonic technique. It is flexible to fold during the transport and installation on construction site. The geocell nets will be filled with soils, granular, cements or other on-site infill materials when stretched into web structures, which has powerful and rigid confinement in the lateral and vertical sides.

terram geocell

Terram Geocell’s Advantages

Enhanced Structural Capacity: Transforms weak, unbound infill into a high-performance structural layer, often reducing required aggregate thickness by up to 50%.

Cost Efficiency: Significant savings on imported high-quality fill materials, transportation, and long-term maintenance. Enables the use of readily available on-site or marginal infill.

Superior Erosion Control: Effectively stabilizes slopes, channels, and shorelines by confining soil and vegetation roots, preventing surface washout.

terram geocell

High-Strength HDPE Material: Ensures durability and flexibility for robust construction.

Lateral Restriction: Provides strong side compression to support soil and stone fillings effectively.

Flexible Design: Can be easily folded and transported, saving space and effort.

Welding Space: Various welding spaces ensure secure connections, enhancing overall stability.

The Specifications of Terram Geocell

| Index Properties | Test Method | Units | Values | ||||||||||||

| Material | 100% Virgin HDPE | ||||||||||||||

| Carbon Black Content | ASTM D 1603 | % | ≥1.5 | ||||||||||||

| Density | ASTM D 1505 | g/cm3 | 0.935-0.965 | ||||||||||||

| Sheet Thickness +5% | ASTM D 5199 | mm | 1.5 | ||||||||||||

| Seam Peel Strength | USACE GL-86-19 | KN/m | ≥14.2 | ||||||||||||

| Tensile Strength at Yield | ASTM D 638 | KN/m | ≥22 | ||||||||||||

| Environmental Stress Crack Resistance ESCR | ASTM D 1693 | hrs | ≥5000 | ||||||||||||

| Oxidation Induction Time OlT | ASTM D 3895 | min | ≥150 | ||||||||||||

| Type No. | DK330 | DK356 | DK445 | DK660 | DK712 | ||||||||||

| Welding Distance(mm)3% | 330 | 356 | 445 | 660 | 712 | ||||||||||

| Cell Depth(mm)+3% | 50,75, 100,150,200,250 | ||||||||||||||

| Dimensions | |||||||||||||||

| Expanded Cell Size (widthxlength)(mm)+3% | 250×210 | 260 x225 | 320 x 288 | 470×450 | 510×475 | ||||||||||

| Expanded Cell Numbers (widthxlength) | 10×34 | 9 x 34 | 8 x 34 | 5 x34 | 5 x 34 | ||||||||||

| Expanded Section Size (widthxlength)(m)+3% | 2.50 x7.14 | 2.34 x 7.65 | 2.56 x 9.8 | 2.35 x 15.3 | 2.55 x 16.15 | ||||||||||

| Expanded Section Area (m2)+5% | 17.85 | 17.9 | 25.1 | 36 | 41.2 | ||||||||||

The Applications of Terram Geocell

Light material, wear resistance, stable chemical performance, light and oxygen aging resistance, acid and alkali resistance,suitable for different soil and desert and other soil conditions.

Higher lateral restraint and anti-skid, anti-deformation and effective enhancement of subgrade bearing capacity and decentralized load.

Geotechnical dimensions such as height and welding distance of geocell can be changed to meet different engineering needs.

Flexibility, small transport volume, convenient connection, make construction more convenient.

terram geocell

terram geocell

terram geocell

terram geocell