Geocell Drainage

Material: HDPE

Height: 50mm-300mm

Welding distance:330mm-1000mm

Application:

Road construction

Retaining walls

Slope peotection

Base stabilization

Channel protection

Geocell Drainage

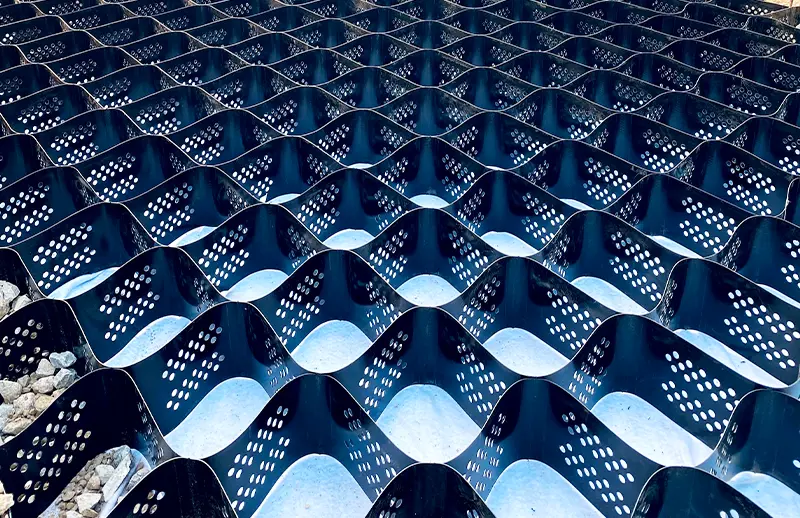

Geocell is mainly made In reinforced HDPE sheet material. After being treated with flame-retardant and antistatic technology, the overall structure of the “double-resistance” plastic net formed by the blaxial stretching method is a new type of high-strength geosynthetic material. A three-dimensional mesh format structure formed by ultrasonic needle welding.

geocell drainage

Geocell Drainage’s Features

3D Cellular Confinement: The unique honeycomb structure effectively confines gravel, sand, soil, or concrete, preventing lateral movement and displacement under load. This dramatically increases the structural integrity of the infill.

Exceptional Load Support: Distributes vertical loads over a wider area, reducing pressure on the subgrade. This makes it ideal for stabilizing weak subgrades for roads, parking lots, railbeds, and construction platforms.

Superior Erosion Control: Effectively stabilizes slopes, channels, and shorelines. By confining topsoil and promoting vegetation growth, it protects against water and wind erosion.

geocell drainage

Flexible & Durable: High resistance to creep, UV degradation, chemical and biological attack. Performs consistently across a wide temperature range with a long design life.

Cost-Effective & Sustainable: Significantly reduces the need for expensive, imported aggregate and base materials. It minimizes excavation, speeds up construction, and lowers long-term maintenance costs. Its lightweight design also reduces transportation and installation expenses.

Easy Installation: Modular panels are lightweight, easy to transport, and quick to deploy. They expand on-site and are secured with anchors. Infilling is done with locally available materials using standard equipment.

The Specifications of Geocell Drainage

| Index Properties | Test Method | Units | Values | ||||||||||||

| Material | 100% Virgin HDPE | ||||||||||||||

| Carbon Black Content | ASTM D 1603 | % | ≥1.5 | ||||||||||||

| Density | ASTM D 1505 | g/cm3 | 0.935-0.965 | ||||||||||||

| Sheet Thickness +5% | ASTM D 5199 | mm | 1.5 | ||||||||||||

| Seam Peel Strength | USACE GL-86-19 | KN/m | ≥14.2 | ||||||||||||

| Tensile Strength at Yield | ASTM D 638 | KN/m | ≥22 | ||||||||||||

| Environmental Stress Crack Resistance ESCR | ASTM D 1693 | hrs | ≥5000 | ||||||||||||

| Oxidation Induction Time OlT | ASTM D 3895 | min | ≥150 | ||||||||||||

| Type No. | DK330 | DK356 | DK445 | DK660 | DK712 | ||||||||||

| Welding Distance(mm)3% | 330 | 356 | 445 | 660 | 712 | ||||||||||

| Cell Depth(mm)+3% | 50,75, 100,150,200,250 | ||||||||||||||

| Dimensions | |||||||||||||||

| Expanded Cell Size (widthxlength)(mm)+3% | 250×210 | 260 x225 | 320 x 288 | 470×450 | 510×475 | ||||||||||

| Expanded Cell Numbers (widthxlength) | 10×34 | 9 x 34 | 8 x 34 | 5 x34 | 5 x 34 | ||||||||||

| Expanded Section Size (widthxlength)(m)+3% | 2.50 x7.14 | 2.34 x 7.65 | 2.56 x 9.8 | 2.35 x 15.3 | 2.55 x 16.15 | ||||||||||

| Expanded Section Area (m2)+5% | 17.85 | 17.9 | 25.1 | 36 | 41.2 | ||||||||||

The Applications of Geocell Drainage

Load Support & Soil Stabilization:

Access roads, haul roads, and parking areas

Railway track beds and embankments

Foundation support for structures and storage yards

Aircraft taxiways and emergency runways

Erosion & Sediment Control:

Slope and channel protection

Retaining walls and earth retention

Shoreline and riverbank reinforcement

Earth Retention & Containment:

Gravity retaining walls

Containment berms for liquids and materials

Special Applications:

Green roofing and landscaping

Sport field foundations

Military and humanitarian rapid deployment projects

geocell drainage

geocell drainage

geocell drainage

geocell drainage

Geocell Drainage

geocell drainage

geocell drainage