One layer geotextile and one layer membrane ; Weight of base geotextile : 100g/m2-1000gm2 ; Thickness of geomembrane :0.1mm-1.5mm .

Two layers geotextile and one layer membrane ; Weight of base geotextile : 80g/m2-600gm2 ; Thickness of geomembrane :0.2mm-1.5mm .

1.One layer geotextile and one layer membrane ; Weight of base geotextile : 100g/m2-1000gm2 ; Thickness of geomembrane :0.1mm-1.5mm .

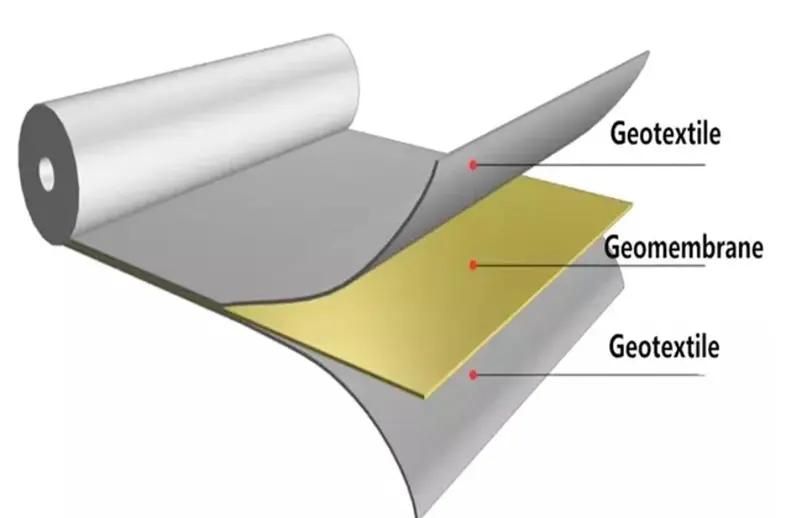

2.Two layers geotextile and one layer membrane ; Weight of base geotextile : 80g/m2-600gm2 ; Thickness of geomembrane :0.2mm-1.5mm .

3.One layer geotextile and two layers membrane ; Weight of base geotextile : 100g/m2-1000gm2 ; Thickness of geomembrane :0.1mm-0.8mm .

4.Multi-layers : Weight of base geotextile : 100g/m2-1000gm2 ; Thickness of geomembrane :0.1mm-1.5mm .

6.Length : 50m-100m

| Properties | Test Method | GMSH050 | GMSH075 | GMSH100 | GMSH150 | GMSH200 |

| Thickness | ASTM D5199 | 0.50 mm | 0.75 mm | 1.00 mm | 1.50 mm | 2.00 mm |

| Density | ASTM D1505 | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc |

| Tensile Properties | ||||||

| Yield strength | ASTM D6693 | 7 kN/m | 11 kN/m | 15 kN/m | 22 kN/m | 29 kN/m |

| Break strength | Type IV | 13 kN/m | 20 kN/m | 27 kN/m | 40 kN/m | 53 kN/m |

| Yield elongation | 12% | 12% | 12% | 12% | 12% | |

| Break elongation | 700% | 700% | 700% | 700% | 700% | |

| Tear Resistance | ASTM D1004 | 62 N | 93 N | 125 N | 187 N | 249 N |

| Puncture Resistance | ASTM D4833 | 160 N | 240 N | 320 N | 480 N | 640 N |

| Stress Crack Resistance | ASTM D5397 | 500 hrs | 500 hrs | 500 hrs | 500 hrs | 500 hrs |

| Carbon Black Content | ASTM D1603 | 2.00% | 2.00% | 2.00% | 2.00% | 2.00% |

| Carbon Black Dispersion | ASTM D5596 | For 10 different views:9 in Categories 1 or 2 and 1 in Category 3 | ||||

| Oxidative Induction Time (OIT) | ASTM D3895 | 100 min. | 100 min. | 100 min. | 100 min. | 100 min. |

| UV Resistance | ASTM D5885 | 50% | 50% | 50% | 50% | 50% |

| High Pressure OIT retained after 1600hrs | ||||||

| Dimensions | ||||||

| Roll Width (m) | 7 | 7 | 7 | 7 | 7 | |

| Roll Length (m) | 420 | 280 | 210 | 140 | 105 | |

HDPE Composite Geomembrane with Geotextile

Features: 1.Good physical and mechanic performance.

2.High tearing resistance, strong deformation adaptability.

3.Puncture-resisting, aging resisting, ultra-violet radiation, oil and salt, and corrosion resistance.

4.Good adaptability to high and low temperature, non-toxicity, long service life.

5.Good waterproof, drainage, anti-seepage and damp proof effects.

6.Complete width and thickness specifications, low cost and easy installation.

Apply to road construction, river levee, lake dam, sewage dam/ waste water dam, channel, liquid storage pool, metro, basement, tunnel, foundation, waste storage, marifarm/seawater farms, freshwater fish farm, /fishpond / aquatic farm, road, high way, expressway/motorway, railway, roofing, and so on.

Production workshop

Tai’an Dingkun New Material Co., Ltd. is a collection of independent research and development, production and sales in a body specialized enterprises. Strong technical force, advanced process equipment, complete product range, has a group of professionals engaged in geotechnical materials production of senior technical staff, and national research institutes, universities established close cooperative relations, the Institute and strong technical force, To ensure product stability and forward looking.

Packing &Transport

Packed in woven geotextile and strength belt or PE film Or packed according to customers’ requirements such as mark the company Logo (Export standard package).

Packaging size and container capacity vary according to product specifications.Dingkun New Material Co., Ltd. can package and transport the products according to the requirements of the customers. please contact us if you need.