Geotextile Materials

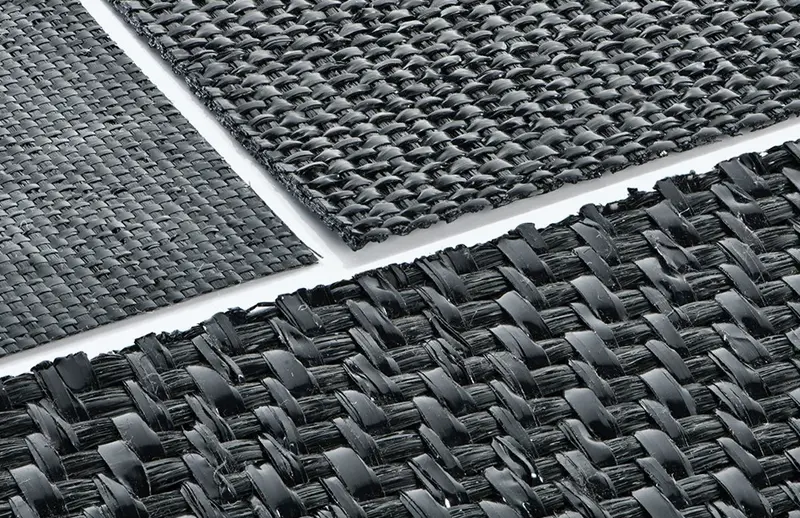

Material: polyester or pp or mixed or recycled

Surface: both sides smooth / both sides textured / one side smooth, the other side textured / as your request

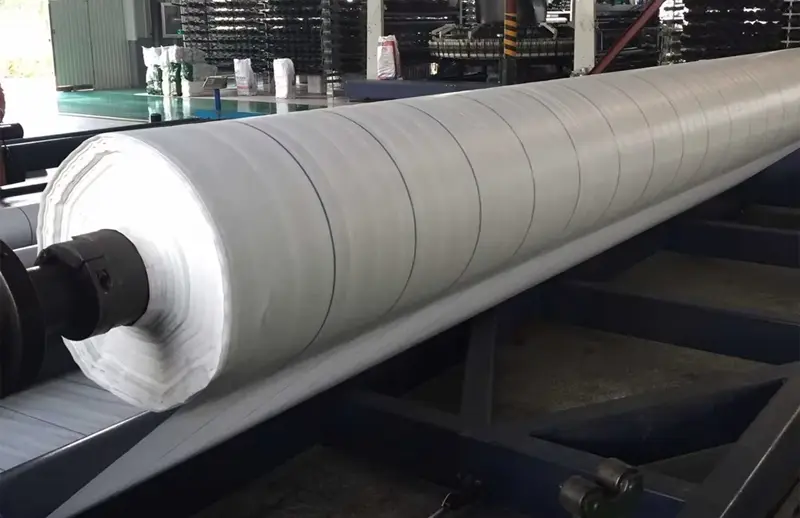

Thickness: 1mm - 5.0mm

Size: Width: 4M - 10M

Length: 50M - 200M (or as request)

Color: Black, White, Blue, Green, Grey , etc

Non-woven geotextile materials are divided into staple fiber needle-punched non-woven geotextile materials and filament spun-bonded

needle-punched non-woven geotextile materials. The main raw materials are PE, PP, etc. Nonwoven geotextile materials are widely used in geotechnical engineering.

Geotextile sed to separate,filter,reinforce, protect or drain. Geotextile materials are commonly used to separate layers like clay and drainage and to protect liner from damage.

Nonwoven geotextile materials punch together to get the stable 3D with highter strength fabric . So nonwoven geotextile materials has high strength , good creep property excellent and erosion resistance, aging-resistance and heat resistance.

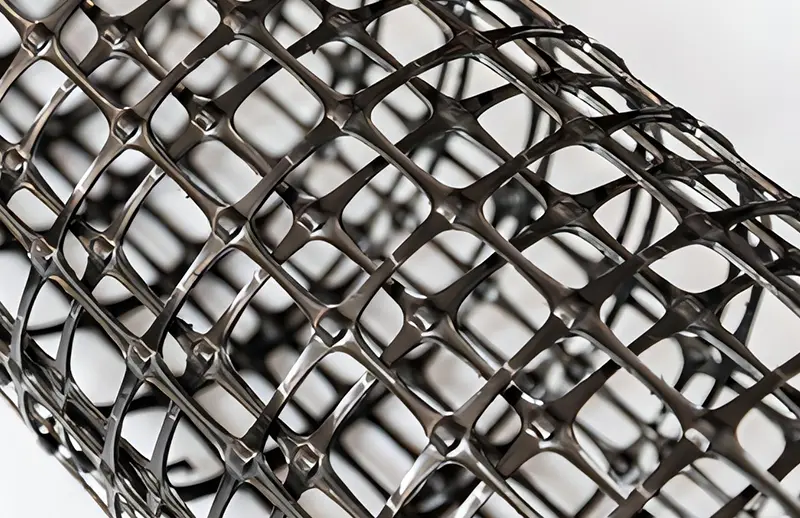

Types of Geotextiles

Woven Geotextile Materials – Manufactured by weaving fibers for high tensile strength, ideal for load-bearing applications like road construction and embankments.

Non-Woven Geotextile Materials – Made by bonding fibers mechanically, thermally, or chemically, offering excellent filtration and drainage properties.

Knitted Geotextile Materials– Less common but used for specialized applications requiring flexibility and durability.

Geotextile Materials

|

Unit weight(g/sqm)

|

Thickness(mm)

|

Breaking strength(kn/m)

|

CBR burst strength(KN)

|

Elongation at break(%)

|

Tear Strength (KN)

|

|

100

|

0.9

|

2.5

|

0.3

|

25-100

|

0.08

|

|

150

|

1.3

|

4.5

|

0.6

|

25-100

|

0.12

|

|

200

|

1.7

|

6.5

|

0.9

|

25-100

|

0.16

|

|

250

|

2.1

|

8.0

|

1.2

|

25-100

|

0.20

|

|

300

|

2.4

|

9.5

|

1.5

|

25-100

|

0.24

|

|

350

|

2.7

|

11.0

|

1.8

|

25-100

|

0.28

|

|

400

|

3.0

|

12.5

|

2.1

|

25-100

|

0.33

|

|

450

|

3.3

|

14.0

|

2.4

|

25-100

|

0.38

|

|

500

|

3.6

|

16.0

|

2.7

|

25-100

|

0.42

|

|

600

|

4.1

|

19.0

|

3.2

|

25-100

|

0.46

|

|

800

|

5.0

|

25.0

|

4.0

|

25-100

|

0.60

|

1. Civil Engineering & Road Construction

a) Pavement & Roadways

Separation Layer: Prevents mixing of subgrade soil and aggregate base, extending road lifespan.

Reinforcement: Reduces rutting and cracking by distributing loads (used in weak soil conditions).

Drainage: Non-woven geotextiles facilitate water flow, preventing waterlogging under pavements.

b) Railway Tracks

Stabilization: Separates ballast from subsoil, reducing track settlement.

Vibration Damping: Minimizes ground vibrations from train movement.

2. Water Management & Hydraulic Engineering

a) Drainage Systems

Landfills: Filters leachate while allowing gas and liquid drainage (used with geocomposites).

French Drains: Wraps perforated pipes to prevent clogging by fine particles.

Retaining Walls: Behind walls to enhance drainage and reduce hydrostatic pressure.

b) Coastal & Riverbank Protection

Erosion Control Mats: Armors slopes against wave action and currents.

Gabion Reinforcement: Lines gabion baskets to improve sediment retention.

Geotube Dewatering: Used in dredging to contain and dewater sludge.

3. Environmental & Landfill Applications

a) Landfill Liners & Caps

Filtration Layer: Prevents soil particles from clogging drainage systems.

Gas Venting: Allows methane escape in landfill covers.

b) Contaminated Soil Remediation

Barrier Fabric: Isolates polluted soil during excavation.

Sediment Control: Silt fences trap runoff particles at construction sites.

4. Agriculture & Landscaping

a) Soil Stabilization

Weed Control: Suppresses weed growth while allowing water penetration.

Green Roofs: Provides drainage and root protection in urban landscaping.

b) Pond & Canal Linings

Underliner Protection: Prevents punctures in geomembranes.

Aquaculture: Used in shrimp/fish ponds for erosion control.

5. Mining & Industrial Applications

a) Tailings Management

Dewatering Bags: Filters mine slurry, separating solids from water.

Heap Leach Pads: Enhances drainage in gold/copper extraction.

b) Access Roads

Soft Ground Stabilization: Enables heavy machinery movement on weak soils.

Challenges: Chemical resistance to acids/alkalis (e.g., polyester for acidic environments).

Applications of Geotextile Materials

High strength, due to the use of plastic fiber,can maintain sufficient strength and elongation under dry and wet conditions.

Corrosion resistance, it can resist corrosion fora long time in soil and water with different pH values.

Good water permeability, with gaps between fibers, so it has good water permeability.

The construction is convenient. Because the material is light and soft, it is convenient to transport, lay and construct.

Durable – Resistant to UV rays, chemicals, and biological degradation.

Cost-Effective – Reduces long-term maintenance and material costs.

Eco-Friendly – Supports sustainable construction by minimizing soil disturbance.

Easy Installation – Lightweight and adaptable to various project needs.