Geotextile Liner

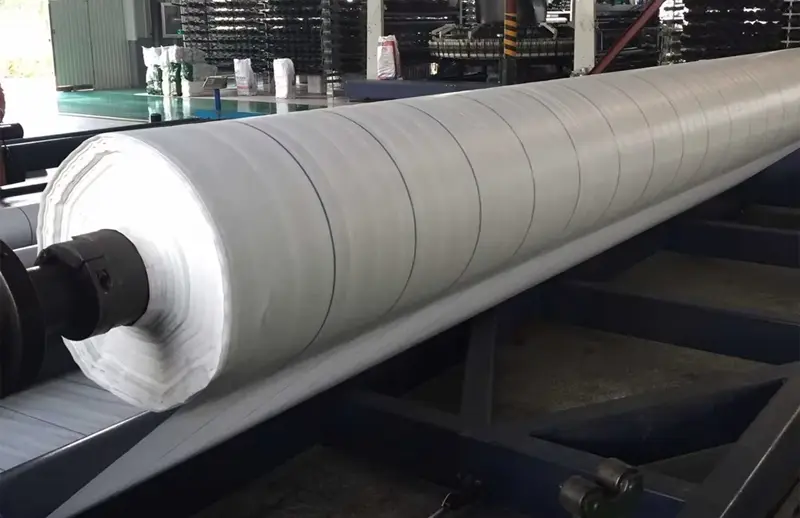

Material:PET/PP

Surface:Filament/Short Fiber

Width:1-6m

Length:50/100/150/200/Customized

Weight:100-1200gsm

Geotextile Liner

Geotextile liner are permeable polymeric fabrics, specifically engineered for use in contact with soil, rock, or any other geotechnical material. As a critical component of modern civil engineering, they provide essential functions such as separation, filtration, drainage, reinforcement, and protection. Our Geotextile liner are manufactured to the highest standards, offering reliable performance, durability, and cost-effectiveness for a vast range of infrastructure and environmental projects.

geotextile liner

Geotextile Liner’s Key Functions

Separation: Prevents the intermixing of distinct soil layers (e.g., aggregate base and soft subgrade), maintaining the integrity and design strength of each layer, which extends service life and reduces maintenance.

Filtration: Allows water to pass through while preventing the erosion and migration of fine soil particles. This is critical for drainage systems, retaining walls, and coastal protection.

Drainage: Facilitates the in-plane flow of water (lateral drainage), relieving pore water pressure and increasing stability in slopes, embankments, and behind structures

geotextile liner

Reinforcement: Provides tensile strength to soil, which has high compressive strength but low tensile capacity. This enables the construction of steepened slopes, reinforced soil walls, and foundations on very soft soils.

Protection: Acts as a cushioning layer to protect sensitive geomembranes (like HDPE liners in landfills) from puncture during installation and from long-term stress.

Geotextile Liner’s Specifications

| Properties | Test Method | Unit | GXSF150 | GXSF200 | GXSF300 | GXSF400 | GXSF500 | GXSF600 | GXSF800 | GXSF1000 |

| Tensile Strength(MD/TD) | ASTM D4595 | kN/m | 8 | 11 | 20 | 24 | 28 | 34 | 48 | 50 |

| Tensile Elongation(MD/TD) | ASTM D4595 | % | 50 | 60 | 60 | 60 | 60 | 60 | 60 | 60 |

| Grab Tensile Strength(MD/TD) | ASTM D4632 | N | 520 | 700 | 1100 | 1500 | 1800 | 2200 | 2800 | 3000 |

| Grab Elongation(MD/TD) | ASTM D4632 | % | 50 | 50 | 60 | 60 | 60 | 60 | 60 | 60 |

| Trapezoidal TearStrength(MD/TD) | ASTM D4533 | N | 220 | 330 | 400 | 480 | 560 | 620 | 860 | 880 |

| CBR Burst Strength | ASTM D6241 | N | 1700 | 2400 | 3200 | 4300 | 5300 | 6000 | 6800 | 7000 |

| Pore Size O90 | ASTM D4751 | m | 90 | 85 | 80 | 75 | 70 | 60 | 55 | 50 |

| Water Flow Q100 | ASTM D4491 | L/m2/s | 160 | 145 | 140 | 120 | 105 | 95 | 90 | 80 |

| Weight | ASTM D5261 | g/m2 | 150 | 200 | 300 | 400 | 500 | 600 | 800 | 1000 |

Geotextile Liner’s Applications

Road & Railway Construction: Separation, stabilization, and reinforcement of subgrades.

Drainage Systems: Wrapping for aggregate drains, behind retaining walls, in sport fields.

Erosion Control: Under riprap, in silt fences, and as a substrate for turf reinforcement mats.

Landfills & Containment: As a protective cushion and separation layer for lining systems.

Soil Reinforcement: In mechanically stabilized earth walls and steep slopes.

Coastal & Riverbank Protection: Filtration beneath revetments and gabions.

Agriculture & Landscaping: Weed barrier, soil stabilization for paths.

geotextile liner

geotextile liner

geotextile liner

geotextile liner

Geotextile Liner

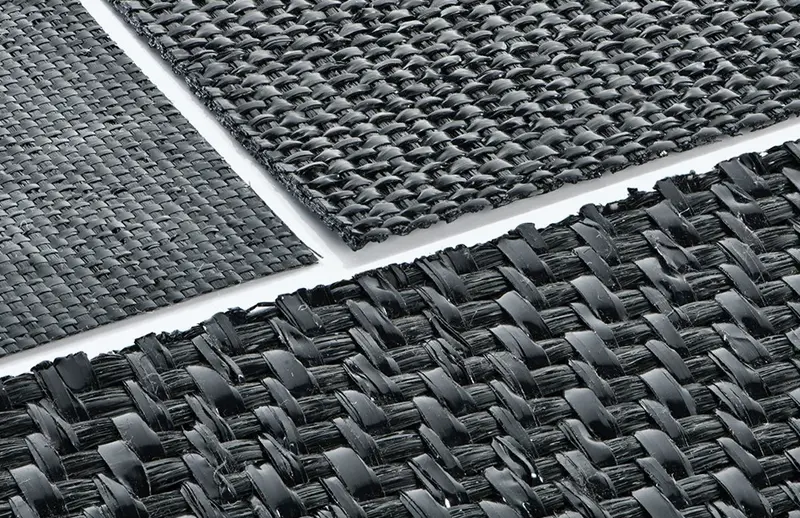

Woven Geotextiles:

Manufacturing: Made by interlacing high-tenacity polypropylene or polyester yarns.

Characteristics: High tensile strength, low elongation, excellent load distribution.

Ideal For: Reinforcement, separation, and base stabilization under roads, railways, and parking areas.

Non-Woven Geotextiles:

Manufacturing: Made from continuous filament or staple fibers bonded mechanically (needle-punched), thermally, or chemically.

Characteristics: Excellent permeability, filtration, and separation properties. Good puncture resistance.

Ideal For: Filtration, drainage, separation, protection (under geomembranes), and erosion control.

Composite Geotextile:

Composite Geotextiles: Combine different fabrics for multifunctional performance.

High-Strength Woven Geotextiles: For demanding reinforcement applications (walls, embankments).

Degradable Geotextiles: Made from natural fibers for temporary erosion control where biodegradation is desired.

geotextile liner

geotextile liner