Geotextile Fabric Non Woven

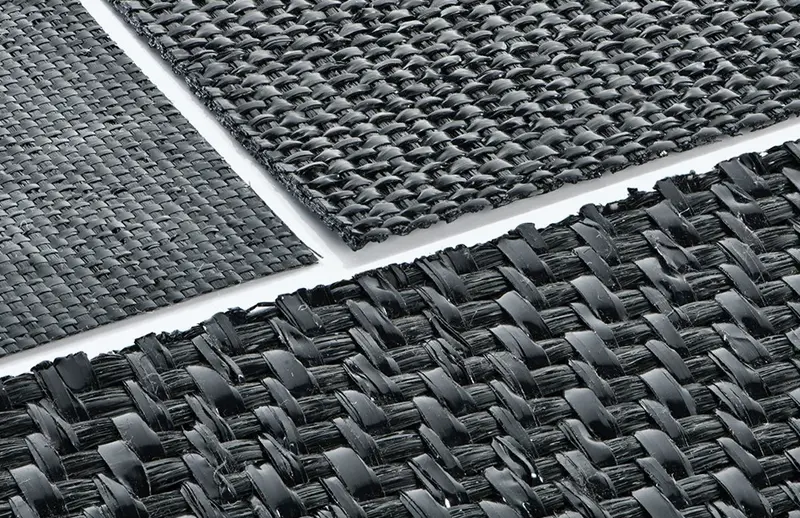

Base Polymer: 100% Virgin Polypropylene (PP) or Polyester (PET)

Fiber Type: Continuous filament or staple fiber

Manufacturing Process: Needle-punched mechanical bonding

Geotextile Fabric Non Woven

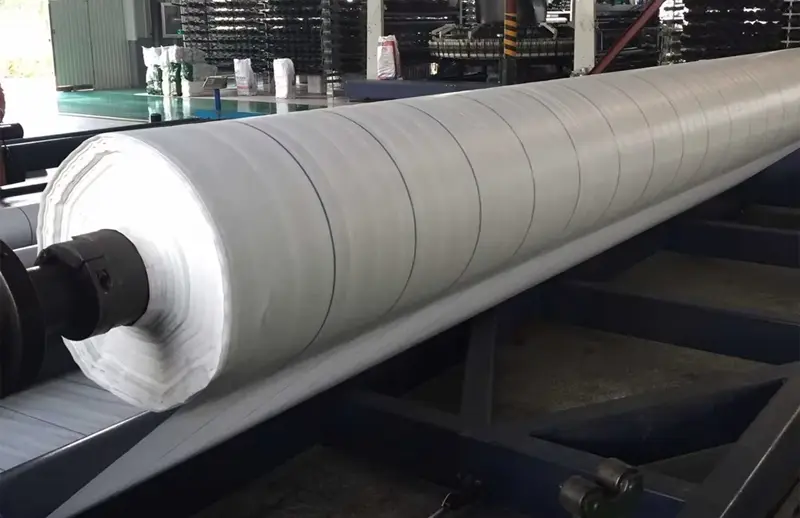

Our state of the art manufacturing facility specializes in the production of high-performance needle-punched non-woven geotextiles. Engineered from 100% virgin polypropylene (PP) or polyester (PET) fibers, our products are designed through precise mechanical entanglement to deliver consistent, reliable performance in separation, filtration, drainage, reinforcement, and protection applications for critical civil and environmental infrastructure projects globally.

geotextile fabric non woven

The Advantages of Geotextile Fabric Non Woven

Easy to Inatall: Save time and money, we stock many sizes to cut down on scrap, one single piece cut to exact dimensions

Made to Last: Will last many years and stands up to the toughest conditions, Superior strength, dimensionally stable, UV/rot resistant

Superior Quality: Super geotextile offers the highest quality products.

Geotextile Fabric Non Woven

Filtration

Prevents soil erosion while maintaining permeability

Separation

Maintains structural integrity

Drainage

Reduces hydrostatic pressure, accelerates consolidation

Reinforcement

Increases bearing capacity, reduces required fill material

Protection

Prevents puncture damage, extends liner lifespan

Geotextile Fabric Non Woven

| Index Properties | Test Method | Unit | Values | ||||||||

| 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | |||

| Color | – | – | White or Black | ||||||||

| Ultimate Tensile Strength, MD | ASTM D4595 | kN/m | 11 | 14 | 17 | 19 | 24 | 27 | 30 | 37 | 41 |

| Ultimate Tensile Strength, TD | ASTM D4595 | kN/m | 10 | 12 | 15 | 17 | 21 | 25 | 28 | 34 | 38 |

| Tensile Elongation | ASTM D4595 | % | 45 | 50 | 50 | 50 | 60 | 60 | 60 | 60 | 60 |

| Grab Tensile Strength, MD | ASTM D4632 | N | 600 | 850 | 1000 | 1250 | 1450 | 1700 | 1900 | 2100 | 2500 |

| Grab Tensile Strength, TD | ASTM D4632 | N | 550 | 700 | 900 | 1100 | 1250 | 1450 | 1600 | 1800 | 2150 |

| Grab Elongation | ASTM D4632 | % | 45 | 50 | 50 | 50 | 60 | 60 | 60 | 60 | 60 |

| Trapezoid Tear Strength, MD | ASTM D4533 | N | 300 | 350 | 430 | 490 | 540 | 630 | 710 | 770 | 920 |

| Trapezoid Tear Strength, TD | ASTM D4533 | N | 270 | 330 | 400 | 450 | 510 | 610 | 690 | 750 | 900 |

| CBR Puncture Strength | ASTM D6241 | N | 1800 | 2300 | 2700 | 3200 | 3600 | 4400 | 4800 | 5800 | 6900 |

| Apparent Opening Size O90 | ASTM D4751 | mm | 0.11 | 0.11 | 0.1 | 0.09 | 0.09 | 0.08 | 0.08 | 0.08 | 0.08 |

| Water Flow Q100 | ASTM D4491 | L/m2/s | 235 | 220 | 200 | 185 | 165 | 125 | 110 | 90 | 80 |

| U.V. Resistance | ASTM D4355 | % @ 500h | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 | 70 |

| Weight | ASTM D5261 | g/m2 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 |

| Thickness | ASTM D5199 | mm | 1.8 | 2.3 | 2.9 | 3.2 | 3.6 | 3.9 | 4.2 | 4.4 | 4.8 |

| Roll Length | – | m | 50-200 | ||||||||

Geotextile Fabric Non Woven

Civil Engineering

Road and highway construction

Railway track bed stabilization

Airport runways and taxiways

Parking lots and driveways

Environmental Engineering

Landfill lining and closure systems

Erosion control on slopes

Drainage and filtration systems

River and coastal protection

Construction

Foundation drainage

Retaining wall backfill

Green roof systems

Sports field construction

geotextile fabric non woven

geotextile fabric non woven

geotextile fabric non woven

geotextile fabric non woven

Geotextile Fabric Non Woven

Geotextile Fabric Non Woven

Geotextile Fabric Non Woven