Geotextile Dewatering Bags

Material: 100% Polypropylene/Polyester

Gsm: 110gsm~800gsm

Width: 81.5*44cm,90*50cm,customized

Color: Black,green,customized

Construction method: Slope greening, repairing mines, inland river improvement,etc

Features: Anti-ultraviolet, anti-aging, non-toxic, non-combustion

Geotextile dewatering bags are tubular geotextile bags made of high-toughness polypropylene yarns with a filtering structure. The geotextile dewatering bags and solidification method involves adding a solution of high-molecular flocculant in a certain proportion to the sludge slurry during underwater dredging, thoroughly mixing it, and then filling it into the geotextile dewatering bags . By leveraging the filtering structure of the equivalent pore size of the geotextile dewatering bags and the internal liquid pressure within the bags as two driving forces, water seeps out of the bags while the sludge remains inside, thereby achieving the effect of reducing the volume of the sludge.

Geotextile Dewatering Bags Feature:

1. Material & Durability

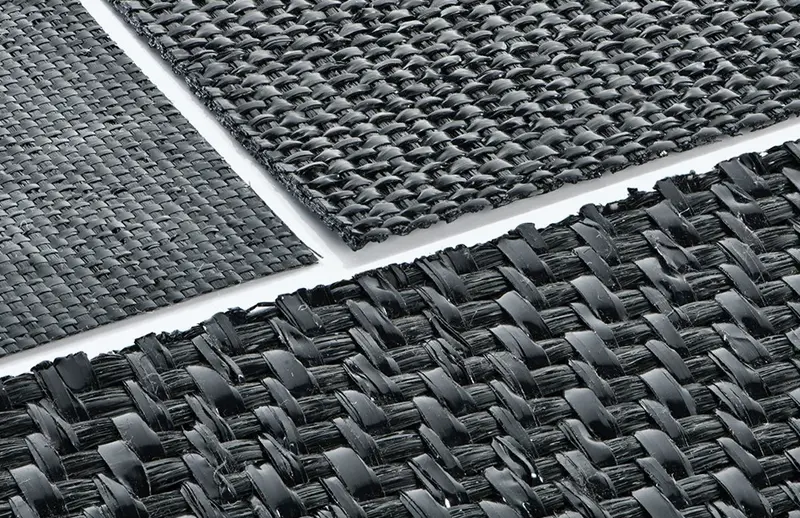

Made from UV-resistant, woven or non-woven geotextile fabric.

High tensile strength to withstand filling, placement, and hydraulic forces.

Resistant to punctures, abrasion, and chemical degradation.

2. Permeability

Allows water to drain out while retaining fine soil particles.

Reduces hydrostatic pressure, improving stability.

3. Flexibility & Adaptability

Can be custom-sized (length, width/Cir.) for different projects.

Conforms to uneven surfaces, making them ideal for erosion control.

Geotextile Dewatering Bags Advantages:

Eco-Friendly – Minimizes environmental impact compared to traditional methods.

Customizable – Available in various sizes and fabric strengths for project-specific needs.

Easy Installation – Can be filled in place using pumps or dredgers.

Geotextile Dewatering Bags Test Report

|

Number |

Experimental Project |

Unit |

Standard |

Standard Value |

Detection Value |

|

|

1 |

Raw Materials |

High Toughness Polypropylene |

||||

|

2 |

Weight |

g/m2 |

GB/T13672 |

≥850 |

857 |

|

|

3 |

Tensile Strength |

Vertical |

kN/m |

SL235-2012 |

≥200 |

223 |

|

|

|

Horizontal |

kN/m |

SL235-2012 |

≥200 |

217 |

|

4 |

Elongation at break |

Vertical |

% |

SL235-2012 |

≤15 |

9.3 |

|

|

|

Horizontal |

% |

SL235-2012 |

≤10 |

7.6 |

|

5 |

Permeability(Q50) |

l/㎡/s |

ISO 11058 |

≥15 |

18 |

|

|

6 |

Equivalent Aperture(O90) |

mm |

GB/T14799-2005 |

0.2-0.6 |

0.45 |

|

|

7 |

Anti-ultraviolet Strength Retention Rate For 500 Hours |

% |

ASTM D4355 |

≥90 |

95 |

|

|

8 |

Factory Stitching Strength |

kN/m |

ISO 10321 |

≥160 |

172 |

|

|

9 |

CBR Puncture Strength(CBR) |

kN |

ISO 12236 |

≥20 |

20.3 |

|

Sludge Dewatering Treatment

The volume of sludge can be reduced by more than 90%, and it contains a higher proportion of solid content, making it easier to remove and process. Separates solids from sludge or dredged material.

Revetment, Breakwater

The embankment core filling geotextile dewatering bags breakwater is a breakwater made of new materials. It forms a kind of breakwater by filling the geotextile dewatering bags with sea sand. Not only saves the construction cost of the breakwater, but also makes better use of environmental resources, and can well meet the construction and functional requiremenrs of the breakwater. Acts as submerged barriers.

Land reclamation

Geotextile dewatering bags technology can dehydrate the bottom mud gathered in river, bays seaports, wharves, ports and docks to project the environment. Creates barriers for sediment control.

Coastal Protection

Geotextile dewatering bags dehydration technology reduces the water content in the filtration process, simplifies the water recycling process,and intercepts more than 90% of the suspended soild particles. It is an ideal choice for cleaning sludge storage tanks,clarification tanks and filtering waster projects.

Erosion Control

Protects shorelines, riverbanks, and slopes.

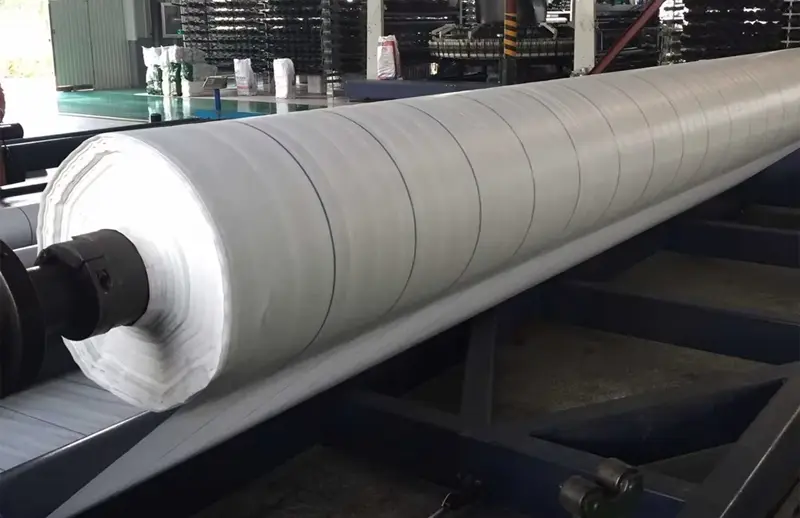

Geotextile Dewatering Bags Production Line

Dingkun New Material Co., Ltd. founded in 2009, is a professional manufacturer of geosynthetic materials with production and sales in one, the company is committed to the research and development, production, sales and export more than ten years, equipped with professional senior technical personnel, to provide customers with high quality, high-quality products and services is the continuous pursuit of Dingkun.

We have 20 most advanced production lines controlled by digital computer in the world.We can produce a variety kinds of geo products such as exhibition carpet, PE, PVA geomembrane,HDPE LDPE waterproofing membrane, composite geomembrane, single direction and biaxial plastic geogrid, warp-knitted geogrid, steel plastic geogrid, geocell, tri-dimension geomat fixing soil, composite waterproofing sheet, geocomposite drain. And all our products adopted national standards, checked and accepted by National and Provincial Technology Supervision Bureau by testing samples.

Welcome to visit our factory!