Geosynthetics Tubes

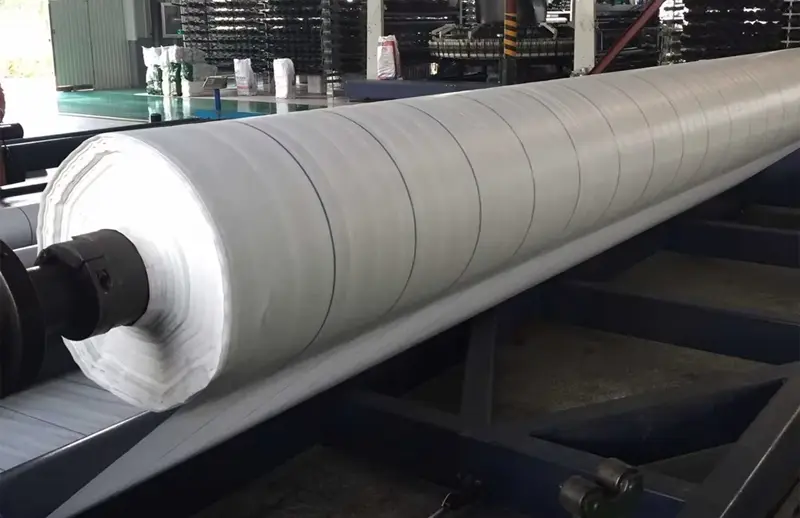

Gsm: 110gsm~800gsm

Width: 81.5*44cm,90*50cm,customized

Color: Black,green,customized

Construction method: Slope greening, repairing mines, inland river improvement,etc

Features: Anti-ultraviolet, anti-aging, non-toxic, non-combustion

A geosynthetics tubes is a tubular geobag constructed from high-strength polypropylene yarn, featuring a permeable woven filtration structure.The geosynthetics tubes dewatering and solidification process works as follows:

During underwater dredging, a high-molecular-weight flocculant solution is mixed into the sludge slurry at a controlled dosage.

The treated slurry is then pumped into the geosynthetics tubes.

Due to the geosynthetics tubes’s precise pore size and internal hydraulic pressure, water filters out through the fabric while the sludge solids are retained inside.

This process effectively reduces sludge volume through dehydration.

Geosynthetics tubes are large, high-strength containers constructed from durable, permeable geotextile fabrics. These engineered systems are designed for efficient solid-liquid separation and erosion control in various environmental and civil engineering applications.With their versatile functionality, geosynthetics tubes provide sustainable, low-impact solutions for sediment management, land reclamation, and infrastructure protection across industries.

Geosynthetics Tubes Test Report

|

Number |

Experimental Project |

Unit |

Standard |

Standard Value |

Detection Value |

|

|

1 |

Raw Materials |

High Toughness Polypropylene |

||||

|

2 |

Weight |

g/m2 |

GB/T13672 |

≥850 |

857 |

|

|

3 |

Tensile Strength |

Vertical |

kN/m |

SL235-2012 |

≥200 |

223 |

|

|

|

Horizontal |

kN/m |

SL235-2012 |

≥200 |

217 |

|

4 |

Elongation at break |

Vertical |

% |

SL235-2012 |

≤15 |

9.3 |

|

|

|

Horizontal |

% |

SL235-2012 |

≤10 |

7.6 |

|

5 |

Permeability(Q50) |

l/㎡/s |

ISO 11058 |

≥15 |

18 |

|

|

6 |

Equivalent Aperture(O90) |

mm |

GB/T14799-2005 |

0.2-0.6 |

0.45 |

|

|

7 |

Anti-ultraviolet Strength Retention Rate For 500 Hours |

% |

ASTM D4355 |

≥90 |

95 |

|

|

8 |

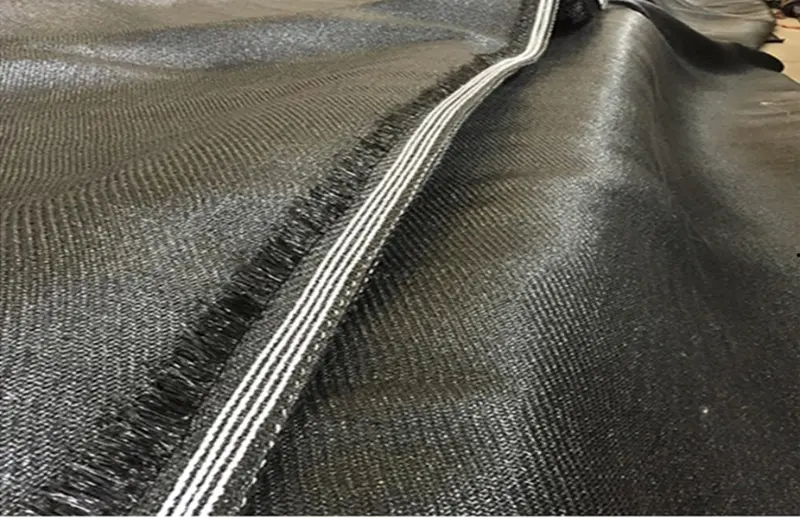

Factory Stitching Strength |

kN/m |

ISO 10321 |

≥160 |

172 |

|

|

9 |

CBR Puncture Strength(CBR) |

kN |

ISO 12236 |

≥20 |

20.3 |

|

When used for dewatering, geosynthetics tubes are filled with slurries such as sediment, sludge, or contaminated dredged materials. The permeable fabric allows water to filter out under hydraulic pressure while retaining the solid particles inside. Over time, the entrapped solids undergo further consolidation, significantly reducing volume and facilitating disposal or reuse.

In coastal and hydraulic engineering, geosynthetics tubes can also be filled with sand or other granular materials to serve as protective barriers. They are widely used in shoreline stabilization, breakwater construction, and flood control due to their flexibility, cost-effectiveness, and resistance to wave action.

Land reclamation

Geosynthetics tubes bag dewatering technology can dehydrate the bottom mud gathered in river, bays seaports, wharves, ports and docks to project the environment. Creates barriers for sediment control.

Coastal Protection

Geosynthetics tubes bag dehydration technology reduces the water content in the filtration process, simplifies the water recycling process,and intercepts more than 90% of the suspended soild particles. It is an ideal choice for cleaning sludge storage tanks,

clarification tanks and filtering waster projects.

Geosynthetics Tubes’s Feature

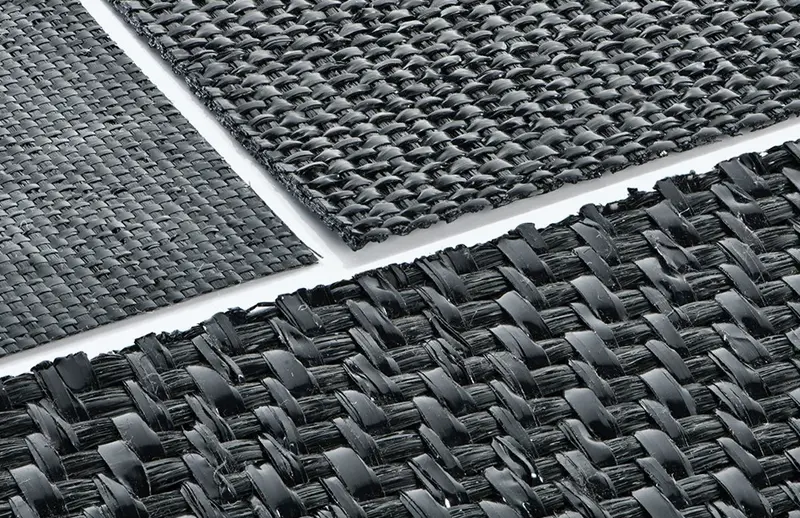

1. Material Composition & Structural Integrity

Fabricated from premium-grade woven/non-woven geotextiles with UV stabilization

Engineered with exceptional tensile strength to endure installation stresses and operational loads

Demonstrates superior resistance to mechanical damage (puncture/abrasion) and chemical deterioration

2. Hydraulic Performance

Optimized filtration characteristics enable efficient water passage with precise particle retention

Effectively dissipates pore water pressure to enhance structural stability

3. Design Versatility & Application Performance

Fully customizable dimensional parameters (length/diameter) to meet project-specific requirements

Exhibits excellent terrain conformity for superior erosion mitigation performance