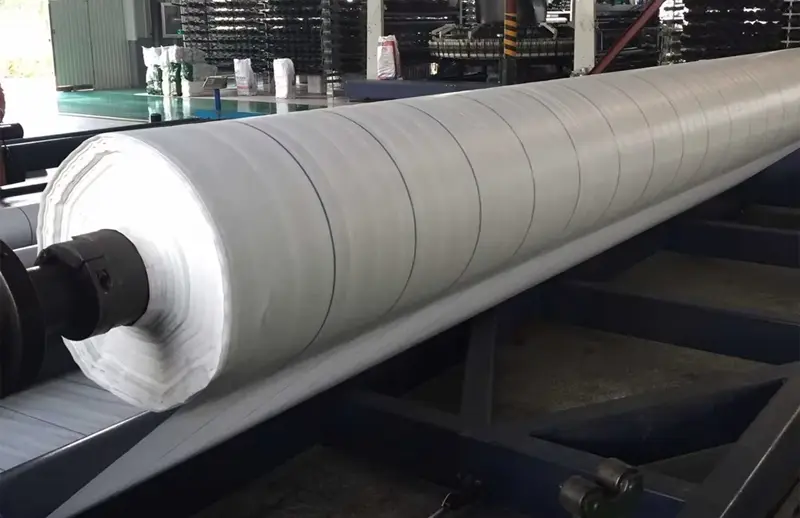

Geomembrane Film

Material: HDPE/LDPE/PVC/EPDM/TPO/LLDPE

Thickness: 0.3mm,0.5mm,0.75mm,1.0mm,1.5mm,2.0mm,3.0mm

Roll Width: 1m,2m,3m,4m,5.8m,6m,7m,8m

Roll Length: 50m,100m,150m,200m

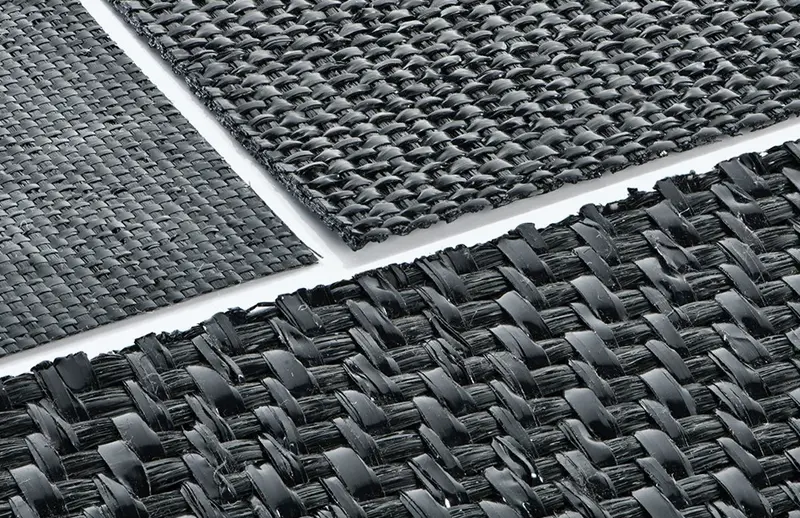

Surface: Smooth,Textured

Colors: Black,Blue,Green,White

Geomembrane Film

Smooth geomembranes film manufactured from quality high density polyethylene resins(HDPE) that comply with the most rigorous requirements established for their use. The 0.5mm hdpe geomembrane is popular thickness,its widely used in aquaculture project,fish pond,shrimp pond and irrigation pond.Smooth Geomembrane, is a geosynthetic material with a flat and smooth appearance.

geomembrane film

Superior Impermeability: Extremely low permeability coefficient, providing an exceptional barrier against liquids, vapors, and gases.

Exceptional Durability: Outstanding resistance to ultraviolet radiation, extreme temperatures, aggressive chemicals, and environmental stress cracking.

High Strength: Excellent tensile, tear, and puncture resistance to withstand installation stresses, subgrade conditions, and long-term loads.

Proven Longevity: Formulated with premium-grade resins and carbon black for UV stabilization, ensuring a service life.

geomembrane film

Primary Material: High-Density Polyethylene (HDPE), the global standard for critical lining applications.

Available Thickness: Ranging from 0.75 mm (30 mil) to 3.0 mm (120 mil) to meet specific design requirements.

Surface Texture: Available in smooth and textured (co-extruded or spray-on) varieties for enhanced interface friction and slope stability.

Panel Sizes: Manufactured in extra-wide sheets (up to 8+ meters) to minimize field seams, delivered in master rolls.

Additives: Customizable with antioxidants, UV stabilizers, and colorants (e.g., black, green) for project-specific needs.

The Specifications of Geomembrane Film

|

Item

|

Index

|

||||||||

|

Thickness (mm)

|

0.30

|

0.50

|

0.75

|

1.00

|

1.25

|

1.50

|

2.00

|

2.50

|

3.00

|

|

Density ( g/cm3)

|

≧0.940

|

||||||||

|

Tensile yield strength (N/mm)

|

≧4

|

≧7

|

≧10

|

≧13

|

≧16

|

≧20

|

≧26

|

≧33

|

≧40

|

|

Tensile fracture strength (N/mm)

|

≧6

|

≧10

|

≧15

|

≧20

|

≧25

|

≧30

|

≧40

|

≧50

|

≧60

|

|

Elongation at yield (%)

|

_

|

_

|

_

|

≧11

|

|||||

|

Elongation at break (%)

|

≧600

|

||||||||

|

Right-angle tear load (N)

|

≧34

|

≧56

|

≧84

|

≧115

|

≧140

|

≧170

|

≧225

|

≧280

|

≧340

|

|

Puncture strength (N)

|

≧72

|

≧120

|

≧180

|

≧240

|

≧300

|

≧360

|

≧480

|

≧600

|

≧720

|

|

Carbon black content (%)

|

2.0~3.0

|

||||||||

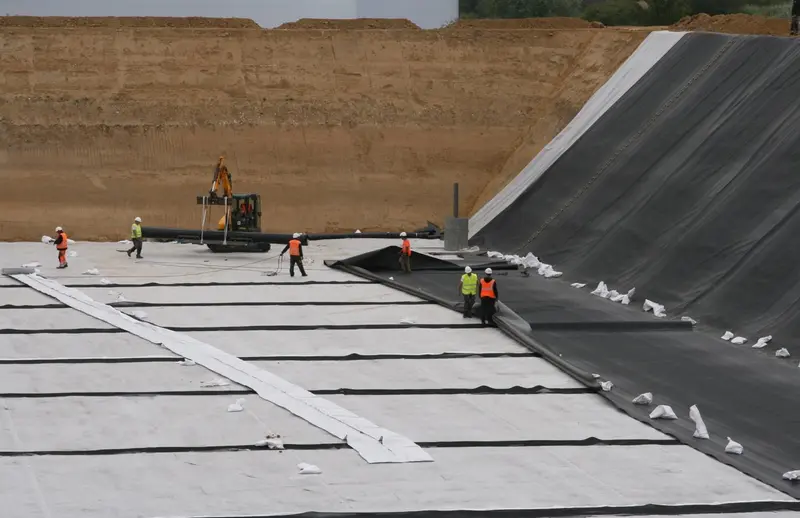

Geomembrane Film’s Application

Geomembrane film is widely used: landfill liners, fish ponds in aquaculture, lining of shrimp ponds, agricultural reservoirs, artificial lakes, reservoirs, seepage prevention in chemical plants, tailings, construction projects, etc. Geomembrane film is a continuous flexible film made of polymer synthetic materials with excellent waterproof and isolation properties.

Environmental Containment:

Landfill base liners & caps (solid waste, hazardous waste)

Heap leach pads & tailings impoundments (Mining)

Wastewater treatment lagoons & evaporation ponds

Secondary containment for fuel and chemical storage

Water & Hydraulic Projects:

Potable water reservoirs & irrigation canals

Decorative & fire protection ponds

Aquaculture & aquaculture pond liners

Canal lining for seepage prevention

Civil & Geotechnical Engineering:

Tunnel and underground waterproofing

Green roof and below-grade water barriers

Vapor barriers for construction

geomembrane film

geomembrane film

geomembrane film

geomembrane film

Geomembrane Film

Zero Permeability: Extremely low hydraulic conductivity forms an impervious barrier, preventing seepage and contamination.

Superior Chemical Resistance: Excellent resistance to a wide range of chemicals, hydrocarbons, and aggressive leachates, ensuring long-term stability.

Exceptional Durability: UV-stabilized formulations resist environmental degradation, punctures.

High Strength & Flexibility: Outstanding tensile, tear, and puncture resistance accommodates subgrade settlement and installation stresses.

Geomembrane Film

Geomembrane Film