Geocell Retaining Walls

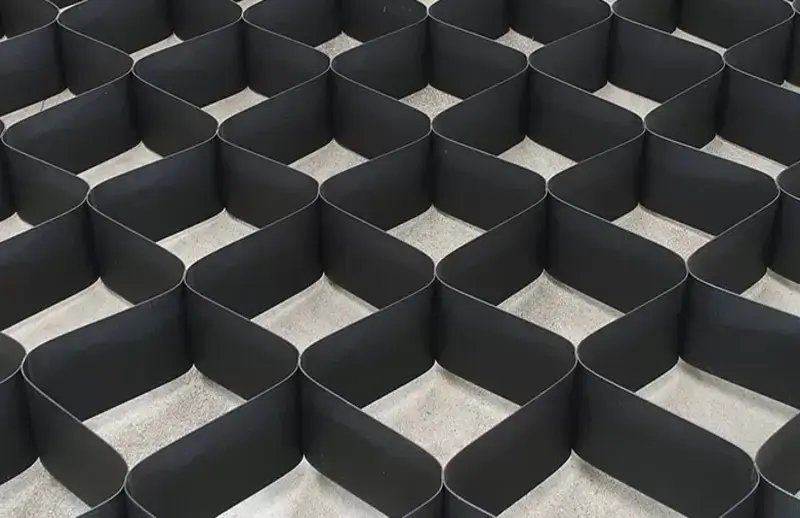

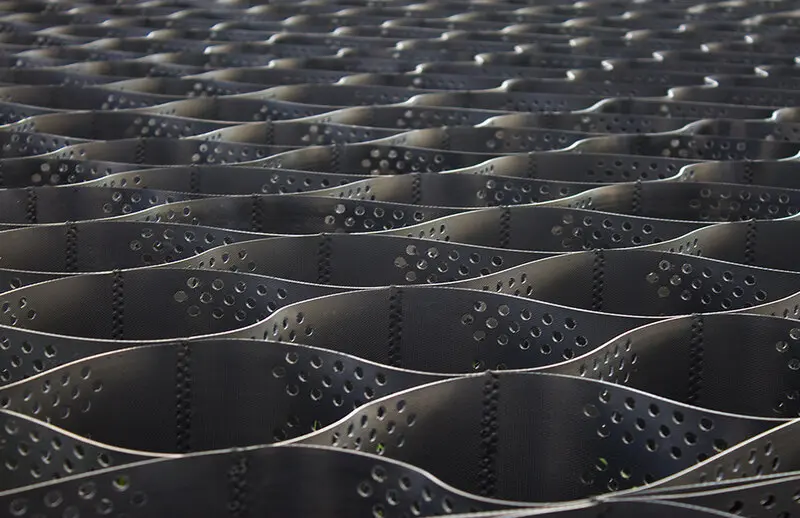

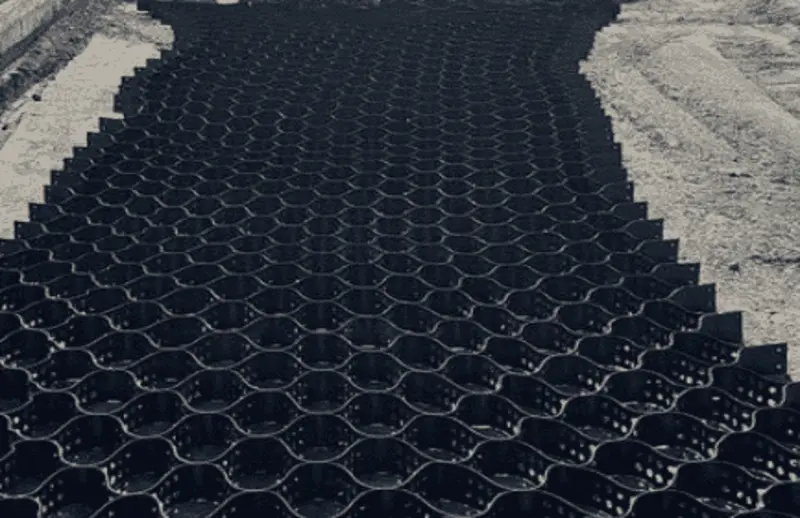

Geocell is a net-shaped cell structure made from high density polyethylene by welding high intensity thermoplastic sheet.

Geocell Retaining Walls

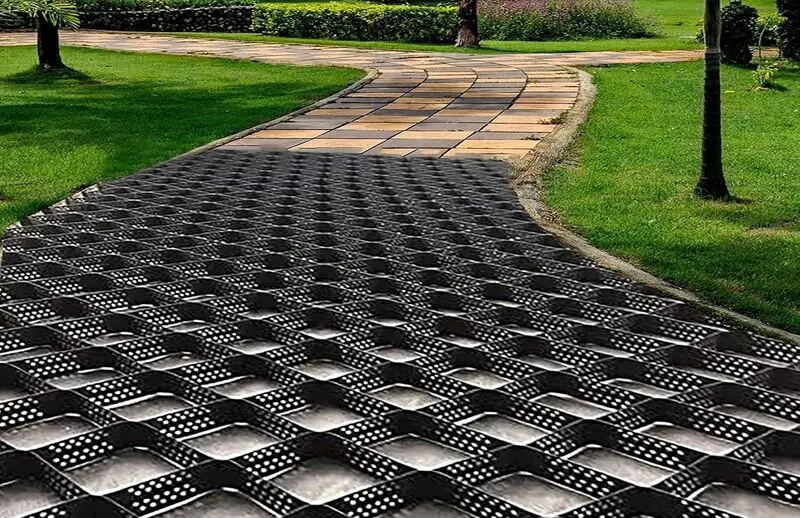

In the world of civil engineering and construction, the challenge of creating stable, durable, and economical retaining structures is constant. Traditional methods like concrete walls or gravity structures can be expensive, time-consuming, and inflexible. Introducing Geocell Retaining Walls – the advanced, cellular confinement system that offers a superior alternative for a wide range of applications.

geocell retaining walls

Geocell Retaining Walls-Exceptional Durability

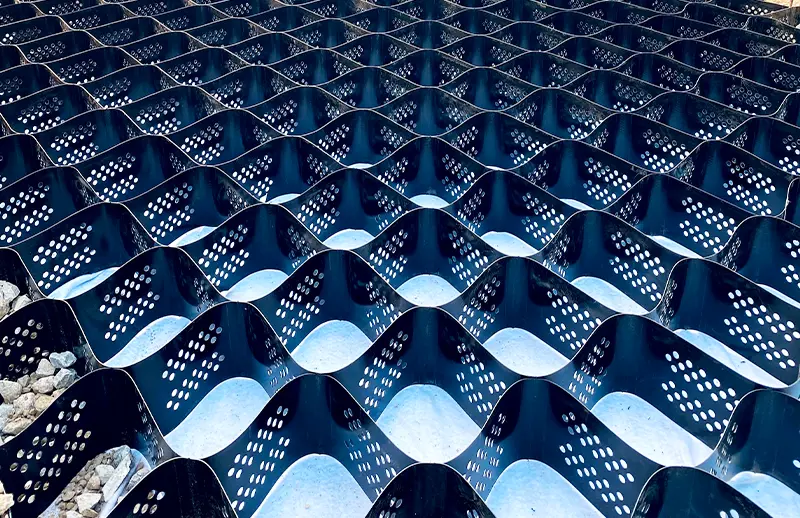

Manufactured from premium, UV-stabilized HDPE polymer, our geocell retaining walls is engineered for long-term performance. It offers excellent resistance to creep, chemical and biological degradation, and harsh environmental conditions, ensuring project integrity for decades.

Geocell Retaining Walls-Rapid, Simple Installation

Geocell retaining walls systems are lightweight and easy to transport and handle. They can be deployed quickly by a small crew with minimal equipment, significantly accelerating project timelines and reducing labor and machinery costs.

Geocell Retaining Walls-Flexibility and Adaptability

Geocell retaining walls is highly flexible and can conform to uneven subgrades and settle without losing structural integrity. This makes it highly resistant to seismic activity and ground movement.

geocell retaining walls

Geocell Retaining Walls-3D Cellular Confinement

The core mechanism of Geocell is its ability to provide all-around confinement to the infill material. This drastically increases the load-bearing capacity and stiffness of the infill, allowing it to distribute loads over a wider area and resist vertical and lateral forces.

Geocell Retaining Walls-Cost Effectiveness

By efficiently confining locally available, on-site infill materials (often reducing the need for high-quality imported aggregates), Geocell retaining walls delivers substantial savings in both material and transportation costs.

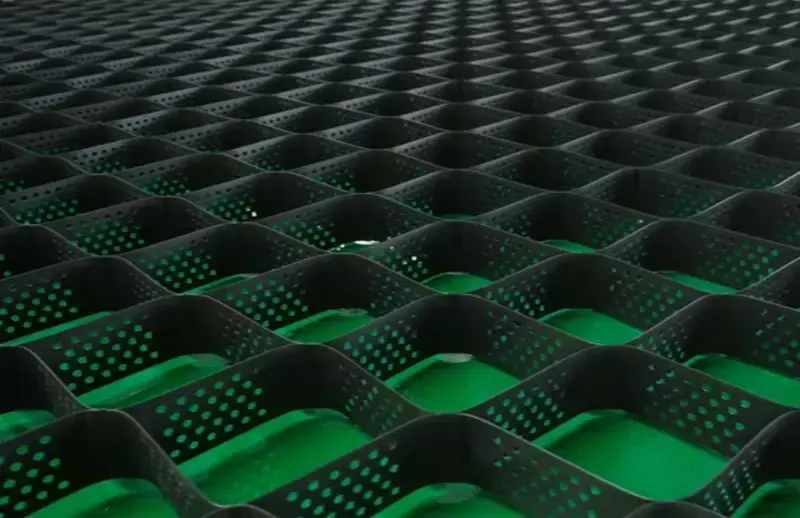

Geocell Retaining Walls-Permeable and Eco-Friendly

The system is naturally permeable, facilitating excellent drainage and preventing water buildup. It promotes vegetation growth when filled with soil, making it an ideal solution for sustainable, green engineering projects that minimize environmental impact.

| Index Properties | Test Method | Units | Values | |||||||

| Material | – | – | 100% Virgin HDPE | |||||||

| Carbon Black content | ASTM D 1603 | % | ≥1.5 | |||||||

| Density | ASTM D 1603 | g/cm3 | 0.935-0.965 | |||||||

| Sheet Thickness ± 3% | ASTM D 5199 | mm | 1.5 | |||||||

| Seam Peel Strength | USACE GL-86-19 | KN/m | ≥14.2 | |||||||

| Tensile strength at Yield | ASTM D 1603 | KN/m | ≥22 | |||||||

| Environmental stress crack resistance | ASTM D 1603 | hrs | ≥5000 | |||||||

| OIT oxidation induction time | ASTM D 1603 | min | ≥150 | |||||||

| Type | GM330 | GM356 | GM400 | GM432 | GM445 | GM500 | GM660 | GM712 | ||

| Welding Distance(mm) ± 3% | 330 | 356 | 400 | 432 | 445 | 500 | 660 | 712 | ||

| Cell Depth(mm) ± 3% | 50,75,100,150,200,250 | |||||||||

| Dimensions | ||||||||||

| Expanded Cell Size (width×length) (mm) ± 3% | 250 x 210 | 260 x 225 | 290 x 260 | 320 x 275 | 315 x 300 | 360 x 300 | 470 x 450 | 510 x 475 | ||

| Expanded Cell numbers(width×length) | 10 x 34 | 9 x 34 | 8 x 34 | 8 x 34 | 8 x 34 | 7 x 34 | 5 x 34 | 5 x 34 | ||

| Expanded Section size (width×length) (m) ± 3% | 2.50 x 7.14 | 2.34 x 7.65 | 2.32 x 8.84 | 2.56 x 9.35 | 2.52 x 10.2 | 2.52 x 11.22 | 2.35 x 15.3 | 2.55 x 16.15 | ||

| Expanded Section Area (m2) ± 5% | 17.85 | 17.9 | 20.5 | 23.94 | 25.7 | 28.74 | 35.95 | 41.18 | ||

The versatility of Geocell retaining walls makes it suitable for a wide range of civil engineering and construction applications:

Load Support & Soil Stabilization:

Foundation reinforcement for roads, railways, and parking lots.

Stabilizing weak subgrades for construction platforms and access roads.

Erosion Control & Slope Protection:

Reinforcing steep embankments and channel linings.

Protecting shorelines and riverbanks from scour and wave action.

Earth Retention:

Constructing cost-effective retaining walls and gravity structures.

Hydraulic Applications:

Linings for reservoirs, dams, and stormwater channels.

Why Choose Our Geocell Retaining Walls?

Significant Cost Savings: Reduce material costs by up to 50% compared to concrete walls. Lower transportation and labor expenses further enhance your project’s ROI.

Environmental Sustainability: By utilizing locally available infill materials (often on-site soil), we minimize the carbon footprint associated with quarrying and transporting large volumes of rock or concrete. The system also promotes vegetation growth, enhancing green infrastructure.

Design Versatility: Geocell walls can be constructed to various heights and angles, and can be easily landscaped to blend seamlessly with the natural environment.

Proven Performance: Our products meet and exceed international quality standards and are backed by extensive research and successful project histories worldwide.