Geocell for Road

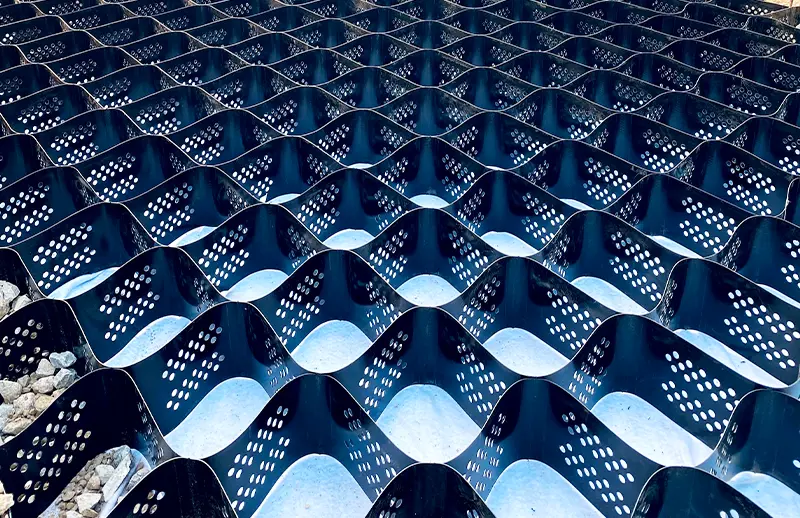

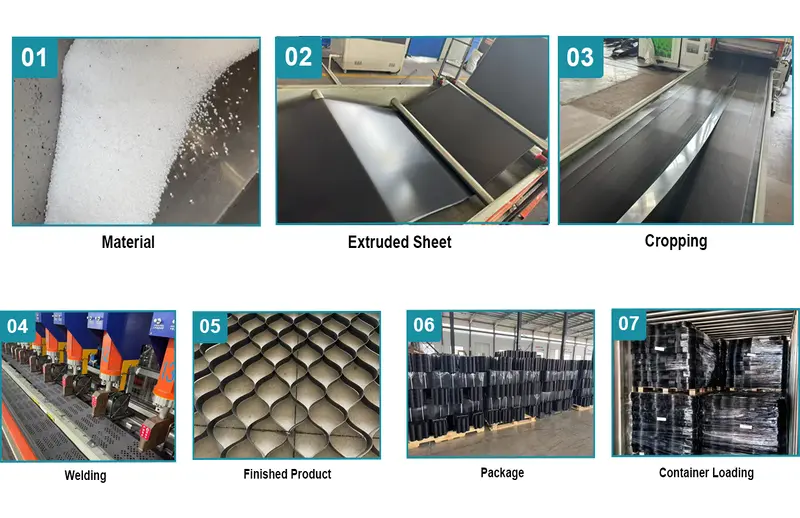

Geocell is a three-dimensional mesh cell structure formed by high-strength welding of reinforced HDPE sheet material. Generally made by ultrasonic needle welding.

Geocell for Road

geocell for road

A geocell (also known as a cellular confinement system) is a three-dimensional, honeycomb-like structure made from strips of polymer materials welded together in a series of interconnected cells. When expanded on-site and filled with soil, aggregate, or concrete, it forms a rigid and durable mat that significantly enhances the load-bearing and erosion control capabilities of infill materials.

HDPE (High-Density Polyethylene): The most common material, offering excellent durability, chemical resistance, and long-term performance in a wide range of environmental conditions. HDPE geocells are UV-stabilized for extended exposed applications.

geocell for road

Main Feature:

1.Light material, wear resistance, stable chemical performance, light and oxygen aging resistance, acid and alkali resistance, suitable for different soil and desert and other soil conditions.

2.Higher lateral restraint and anti-skid, anti-deformation and effective enhancement of subgrade bearing capacity and decentralized load.

3.Geotechnical dimensions such as height and welding distance of geocell can be changed to meet different engineering needs.

4. Flexibility, small transport volume, convenient connection, make construction more convenient.

| Index Properties | Test Method | Units | Values | |||||||

| Material | – | – | 100% Virgin HDPE | |||||||

| Carbon Black content | ASTM D 1603 | % | ≥1.5 | |||||||

| Density | ASTM D 1603 | g/cm3 | 0.935-0.965 | |||||||

| Sheet Thickness ± 3% | ASTM D 5199 | mm | 1.5 | |||||||

| Seam Peel Strength | USACE GL-86-19 | KN/m | ≥14.2 | |||||||

| Tensile strength at Yield | ASTM D 1603 | KN/m | ≥22 | |||||||

| Environmental stress crack resistance | ASTM D 1603 | hrs | ≥5000 | |||||||

| OIT oxidation induction time | ASTM D 1603 | min | ≥150 | |||||||

| Type | GM330 | GM356 | GM400 | GM432 | GM445 | GM500 | GM660 | GM712 | ||

| Welding Distance(mm) ± 3% | 330 | 356 | 400 | 432 | 445 | 500 | 660 | 712 | ||

| Cell Depth(mm) ± 3% | 50,75,100,150,200,250 | |||||||||

| Dimensions | ||||||||||

| Expanded Cell Size (width×length) (mm) ± 3% | 250 x 210 | 260 x 225 | 290 x 260 | 320 x 275 | 315 x 300 | 360 x 300 | 470 x 450 | 510 x 475 | ||

| Expanded Cell numbers(width×length) | 10 x 34 | 9 x 34 | 8 x 34 | 8 x 34 | 8 x 34 | 7 x 34 | 5 x 34 | 5 x 34 | ||

| Expanded Section size (width×length) (m) ± 3% | 2.50 x 7.14 | 2.34 x 7.65 | 2.32 x 8.84 | 2.56 x 9.35 | 2.52 x 10.2 | 2.52 x 11.22 | 2.35 x 15.3 | 2.55 x 16.15 | ||

| Expanded Section Area (m2) ± 5% | 17.85 | 17.9 | 20.5 | 23.94 | 25.7 | 28.74 | 35.95 | 41.18 | ||

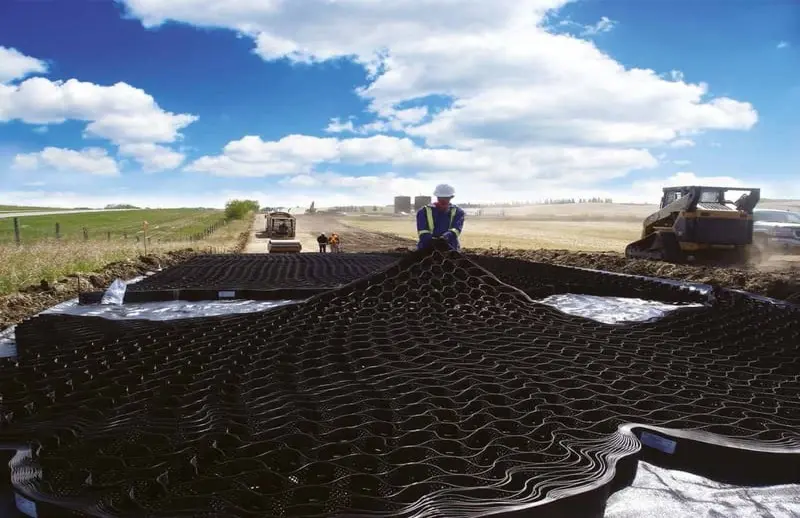

Geocell for Road’s Applications

1.Road support:solve problems on damaged roads, parking lot and yard;

2.Slope protection: create a stable environment for long-term sustainability of embankment material;

3.Channel protection: ensure stability and protection of chanels exposed to all types of erosive conditions;

4.Vegetated retaining walls: inclueds steep slopes, retaining walls, gravity walls and so on.

Geocell for Road

All products are inspected by professional technicians so the highest standards can be met. Quality control is always our top priority to keep our customers satisfied.

Geocell for Road

Geocell for Road’s Package

Packed in woven geotextile and strength belt or PE film Or packed according to customers’ requirements such as mark the company Logo (Export standard package). Packaging size and container capacity vary according to product specifications.

We can package and transport the products according to the requirements of the customers. please contact us if you need.