Our Company

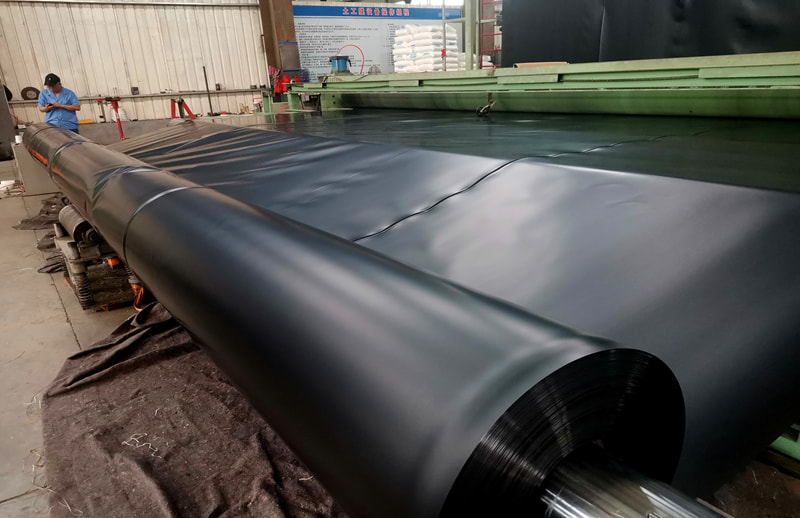

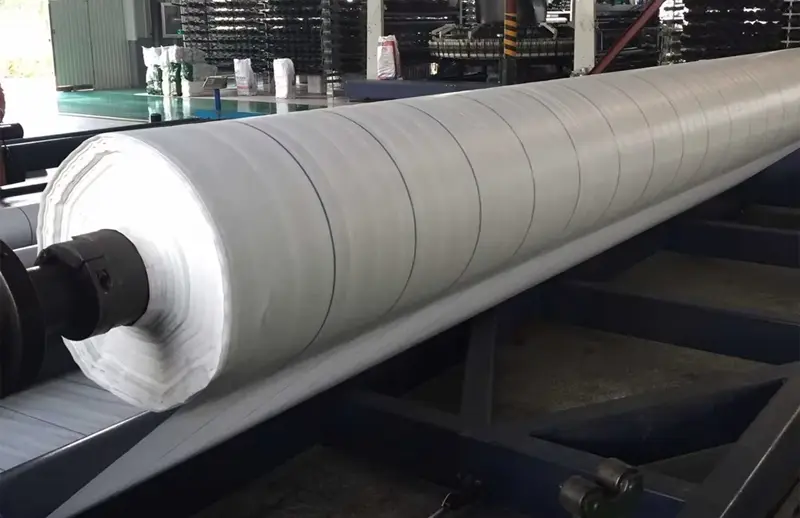

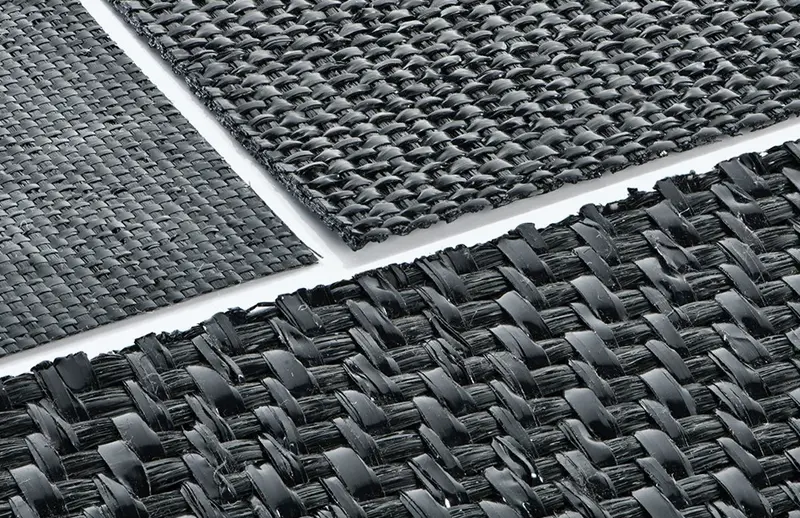

Dingkun New Material Co., Ltd., founded in 2009, located in Taian, Shandong Province, is the leading manufacturer of geosynthetic products. Our factory covers an area of 200,000 square meters, with an annual production output of 80 million square meters of various geosynthetics products. Our main products include geomembrane, geocell, geogrid, geotextile, geomat,CCL(geosynthetics clay liner), all certified by lSO. DINGKUN not only produces the highest quality geosynthetics, geomembrane, geotextile products, but also provides professional design and installation services. OEM and ODM are also available.

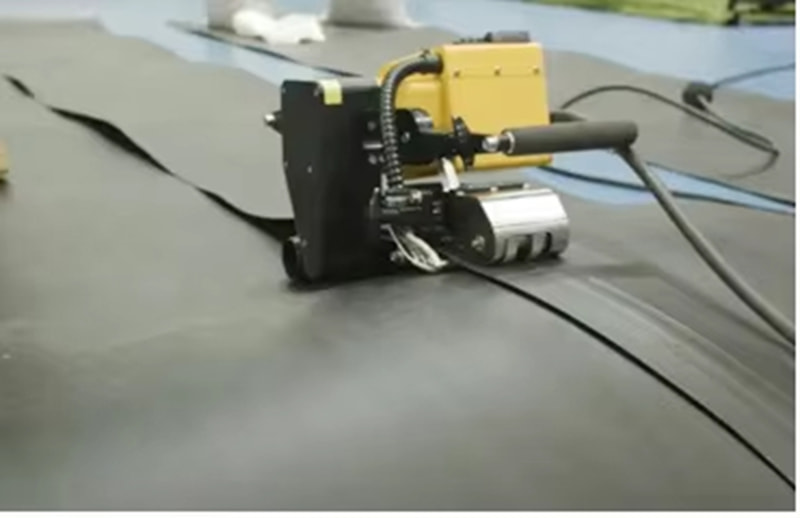

Product Mounting

Welding is necessary during Installation of geomembrane lining systems, which needs to be conducted by a professional welder. The two common welding techniques applied during geomembrane installation are:

1, Double hot metal wedge welding

2, Extrusion welding —the most reliable and suitable method is double hot metal wedge welding