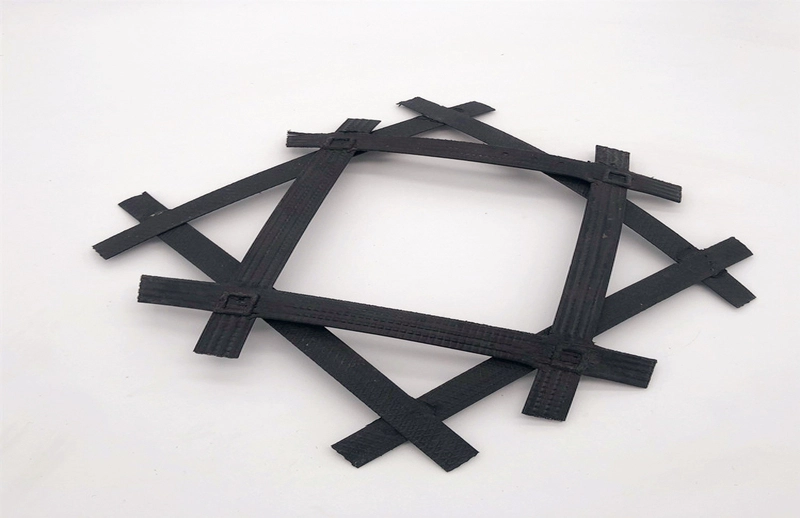

Steel Plastic Geogrid

Material: Steel Plastic

Feature: Flexible, Eco-Friendly, Durable

Roll Length: 50-75-100-150-200mm

Welding distance: 330-1000mm

Thickness of smooth geocell: 1.1mm-1.2mm

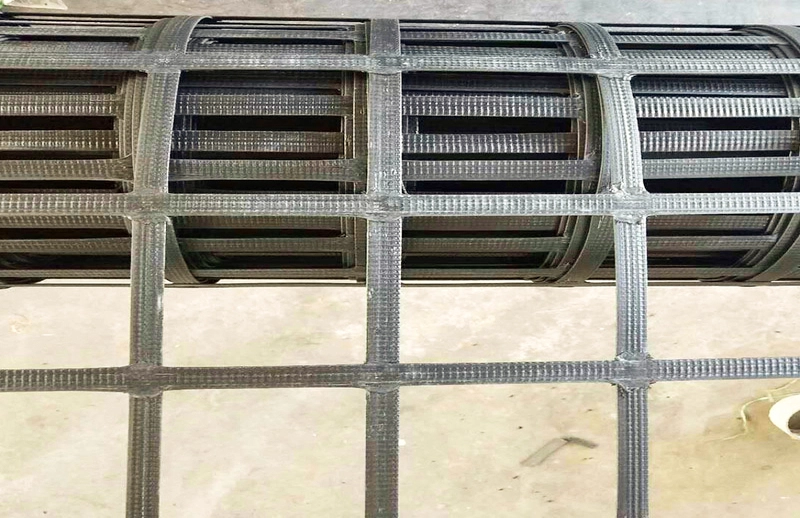

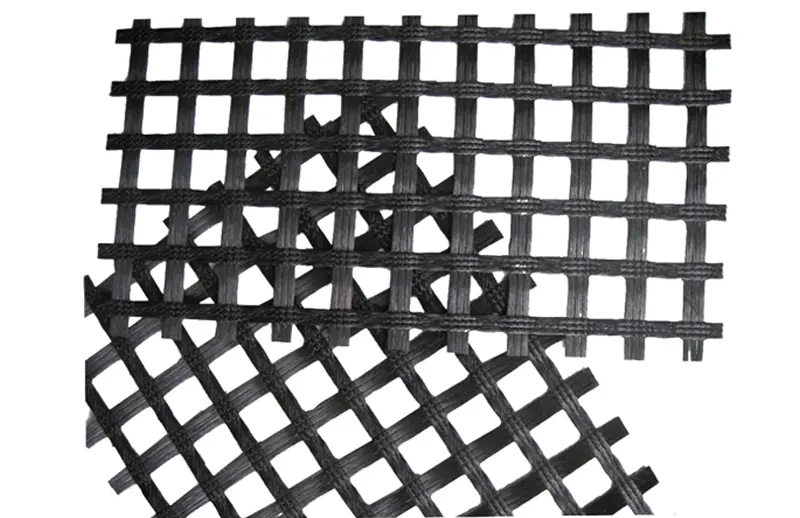

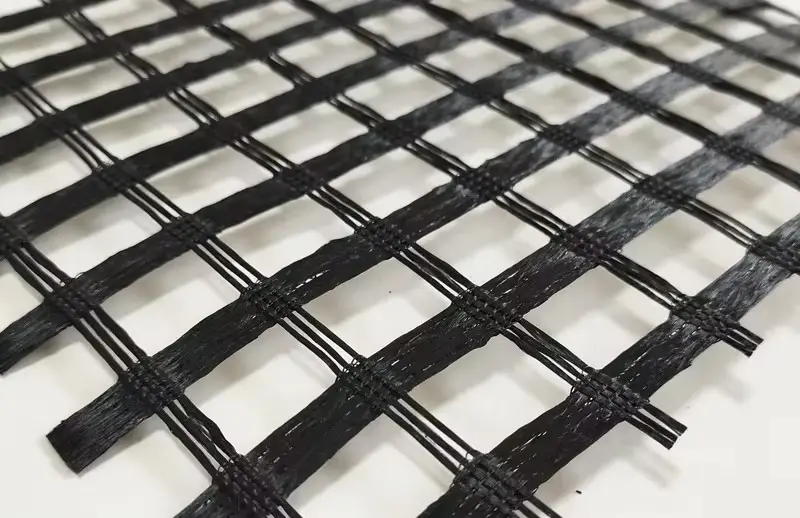

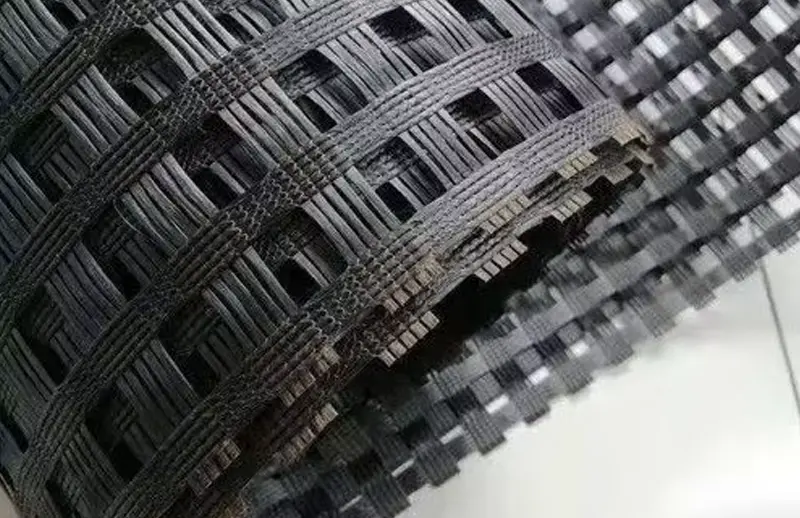

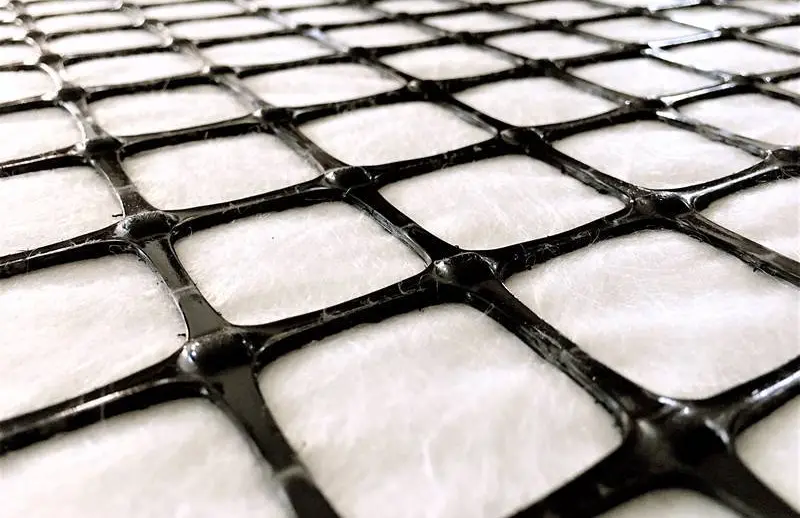

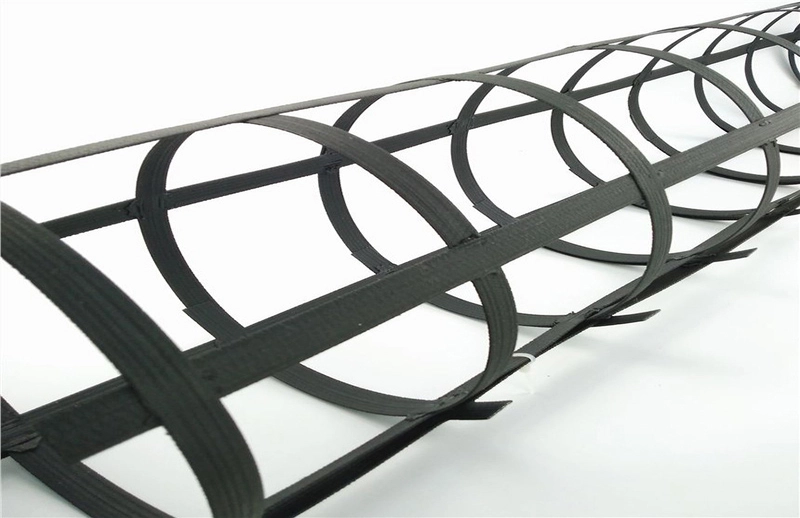

Biaxial steel plastic geogrid is made of longitudinal and transverse steel-plastic composite ribs as the force-bearing element, and the junction is processed by ultrasonic and other special technology to form a high tensile strength, good integrity of the grid-like sheet, the application of the soil and the common force play a strong embedded locking effect, so as to maintain good overall stability performance. It can be used in civil engineering such as highway, railroad, embankment, bridge platform, construction road, wharf, shore protection, flood control dike, dam, beach management, cargo yard, slag field, airport, sports field, environmental protection building, soft ground reinforcement, retaining wall, slope protection and pavement anti-deterioration.

Steel plastic geogrid can effectively improve the interlocking and occluding effect of the reinforced bearing surface, greatly enhance the bearing capacity of the foundation, effectively restrain the lateral displacement of the soil, and enhance the stability of the foundation.High strength, small creep, suitable for all kinds of environmental soil, can fully meet the use of high-grade highway retaining wall.

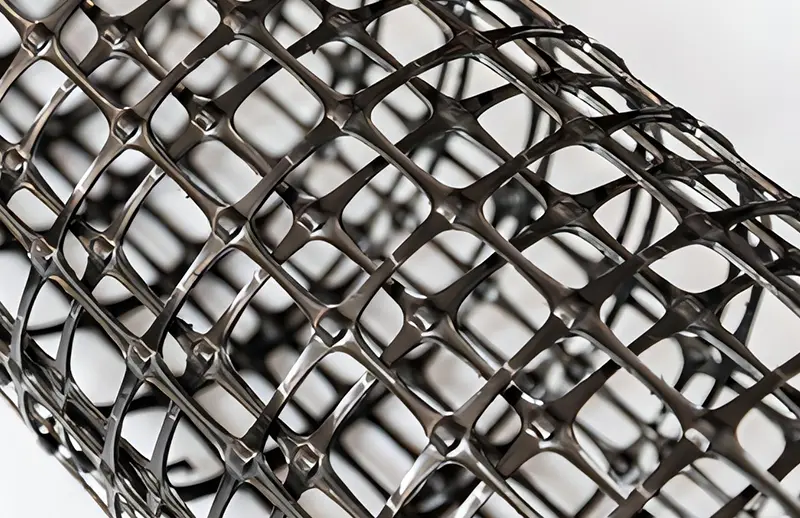

Steel plastic geogrid is manufactured by positioning high-tensile steel wires in a precise grid pattern. These wires are then fusion-bonded with a protective polymer coating under strict quality control. The result is a unified composite structure where the steel core bears the tensile loads, and the plastic coating provides protection and interfacial friction.

Steel Plastic Geogrid Technical Parameters

|

High-strength Steel Plastic Biaxial Geogrid Specification

|

|||||||

|

Performance

/Specification

|

TGDC30-30

|

TGDC45-45

|

TGDC60-60

|

TGDC80-80

|

TGDC100-100

|

TGDC120-120

|

|

|

Two-way Limited Rally (KN/m)>=

|

30

|

45

|

60

|

80

|

100

|

120

|

|

|

Two-way Limited elongation ratio(%)<=

|

3

|

3

|

3

|

3

|

3

|

3

|

|

|

Elongation at a% of the rally (KN/m)>=

|

23

|

36

|

48

|

63

|

81

|

98

|

|

|

Width(m)

|

6m

|

||||||

Reinforced Soil Retaining Walls and Steep Slopes

Foundation Stabilization for Highways, Railways, and Airport Runways

Embankments built over soft soils

Landfill lining systems and closure caps

Parking lots and heavy-load industrial platforms

Erosion control projects

Advantages Over Alternatives

Steel Plastic Geogrid vs. Plastic Geogrids: Offers significantly higher tensile strength and modulus, making it suitable for the most demanding reinforcement projects.

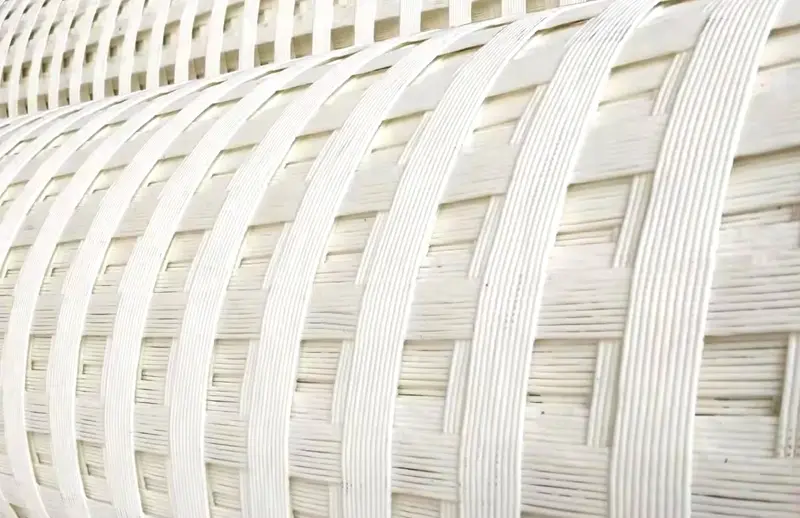

Steel Plastic Geogrid vs. Woven Geotextiles: Provides a more rigid structural reinforcement with much lower creep.

Steel Plastic Geogrid vs. Traditional Steel Mats: Offers superior corrosion resistance, is easier to handle, and is more cost-effective.

Primary Functions

Reinforcement: The primary function is to reinforce soil masses, weak subgrades, and steep slopes by providing tensile strength that the soil inherently lacks.

Stabilization: It stabilizes the soil structure, reduces differential settlement, and increases the overall stability of constructed areas.

Load Distribution: It distributes concentrated loads over a wider area, reducing pressure on the underlying weak subsoil and enhancing the performance of paved and unpaved roads.