Drainage Geonet

Material: HDPE

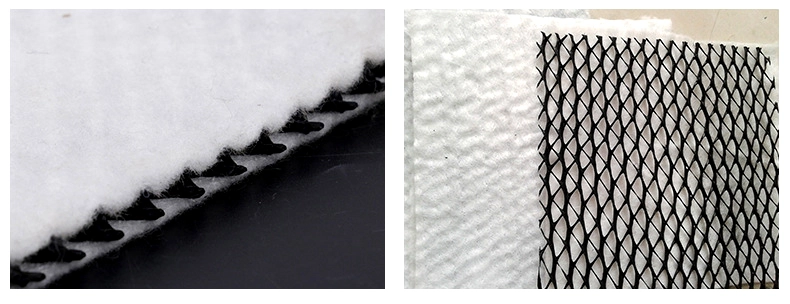

1. Definition and structure

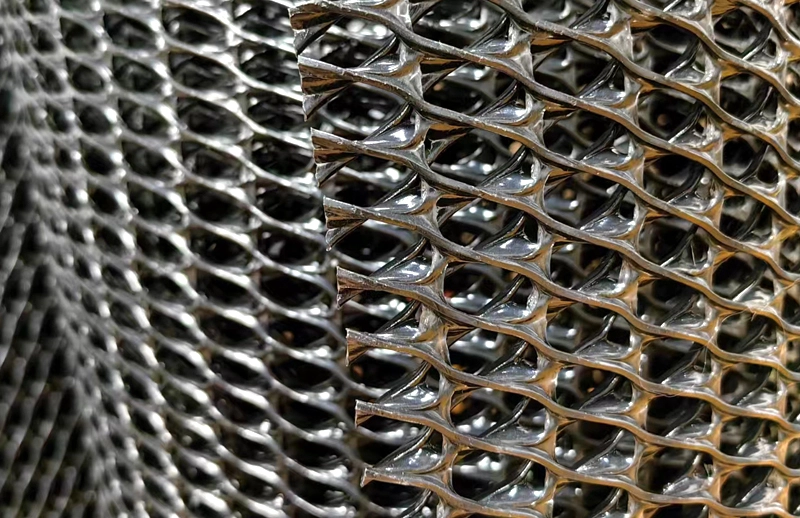

The three-dimensional drainage net is a new type of geosynthetics, which is composed of a three-dimensional plastic net (three-dimensional geonet core) and a double-sided bonded anti-filtration geotextile. Its core structure is a three-dimensional geonet core, which contains a thick vertical rib and an inclined rib at the top and bottom to form a three-dimensional drainage channel.

2. Performance characteristics

Efficient drainage: The three-dimensional structure of the three-dimensional geonet core forms a drainage channel, and the double-sided bonded geotextile has an anti-filtration function, which can quickly discharge groundwater, shorten the drainage path, and lower the groundwater level.

High bearing capacity: The core structure can withstand a compression load of more than 2000kPa, maintain thickness and water conductivity under high pressure, and is suitable for high-load projects.

Anti-blocking and durability: The cross-arranged ribs above and below form a support to prevent the geotextile from being embedded in the drainage channel, reduce the risk of blockage, and extend the service life.

Versatility: It has drainage, anti-filtration, breathability, and protection functions, which can replace the traditional gravel layer and reduce the amount of materials used.

3. Technical parameters

Drainage performance: permeability of 2500m/d (load 720kPa, gradient 2%), flow rate 13pm/m.

Mechanical properties: tensile strength ≥36.5kN/m, melt index 1.0g/10min, thickness 7.6mm.

Geotextile performance: apparent pore size 0.18mm, water permeability 0.26Sec⁻¹, puncture strength 580N.

Durability: Creep test shows that after bearing 1200kPa load for 10,000 hours, the thickness retention rate exceeds 60%.

4. Construction points

Laying direction: The length direction of the material roll is perpendicular to the road.

Joint treatment: The geotextiles of adjacent geonet cores are overlapped along the material roll, and the geonet cores are connected with plastic buckles or polymer belts, connected every 3 feet (about 0.9 meters).

Welding and stitching: The overlap direction of the geotextile is consistent with the stacking direction of the filler, and continuous wedge welding, flat head welding or stitching is required between the foundation/base and the subbase.

Traffic engineering: drainage of highway and railway roadbeds, preventing fine materials from entering the subgrade, and extending the service life of roads.

Landfills: drainage layer for leachate and groundwater, preventing damage to the anti-seepage layer and increasing the landfill volume.

Tunnels and underground projects: drainage of tunnel inner walls and underground structures to ensure project safety.

Retaining walls and slopes: drainage of the back of retaining walls and stable drainage of slopes to prevent damage by water pressure.

Gardens and sports fields: drainage of flower beds and sports fields to keep the soil dry.

Cold areas: reduce the impact of frost heave, limit the development of ice crystals, and ensure spring traffic loads.