Biaxial Geogrid Suppliers

Material : PP(Polypropylene)

Width: 1-6m

Colors : Black

Excellent interlock with granular materials

Reduced aggregate requirements

Enhanced bearing capacity

Biaxial Geogrid Suppliers

Biaxial geogrid is the kind of geosynthetic material which is widely used to reinforce retaining walls, as well as subbases or subsoils below roads or structures. Plastic biaxial geogrid is often made from plastic materials which may be high-density polypropylene or high-density polyethylene (HDPE) resins through the processes of extruding, sheet forming, punching and stretching. Compared with uniaxial plastic geogrid, biaxial plastic geogrid has high tensile strength and excellent tensile modulus in both longitudinal and transverse direction, so the plastic biaxial geogrid can offer superior stiffness, high strength at low strain, aperture stability and interlock capabilities, maximum bearing capacity and shear resistance for for structural reinforcement of paved and unpaved roads. Nuolian brand plastic biaxial geogrid can be used as soil reinforcement below roads, under structures, behind retaining walls, pavement overlays reinforcement, strengthening soft ground of highway, railway, slope protecting projects and airfields, it can also enhance soil structure, prevent soil erosion, increase stability and loading capacity of foundation, prolong the projec life.

Material Excellence

Made from virgin polypropylene or polyethylene

Outstanding resistance to chemical and biological degradation

UV stabilized for exposed applications

Maintenance-free service life

Installation Advantages

Flexible and easy to handle

Lightweight for rapid deployment

Customizable roll sizes available

Compatible with various fill materials

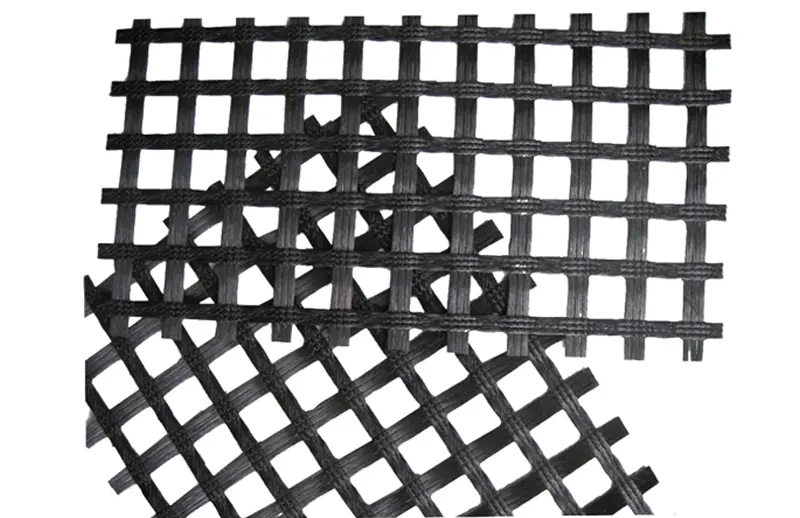

biaxial geogrid suppliers

biaxial geogrid suppliers

Biaxial Geogrid Suppliers’s Specifications

| Index Properties | Test Method | DK15 | DK20 | DK30 | DK40 | DK50 | |

| Ultimate Tensile Strength KN/m) | MD | ASTM D 6637 | 15 | 20 | 30 | 40 | 50 |

| CD | |||||||

| Elongation at Maximum Load (%) | MD | 13 | |||||

| CD | |||||||

| Tensile Strength at 2% Elongation (KN/m) | MD | 5 | 7.5 | 10.5 | 14 | 18 | |

| CD | |||||||

| Tensile Strength at 5% Elongation (KN/m) | MD | 7 | 14 | 21 | 28 | 35 | |

| CD | |||||||

| Minimum Carbon Black(%) | ASTM D 4218 | 2 | |||||

Biaxial Geogrid Suppliers’s Applications

Transportation Infrastructure

Road and railway base reinforcement

Working platform stabilization

Bridge approach support

Parking lot foundation

Earth Retention Systems

Mechanically Stabilized Earth (MSE) walls

Embankment support over soft soils

Slope reinforcement and repair

Levee and dam stabilization

Site Development

Industrial yard stabilization

Storage area foundation support

Port and terminal facilities

Heavy equipment working platforms

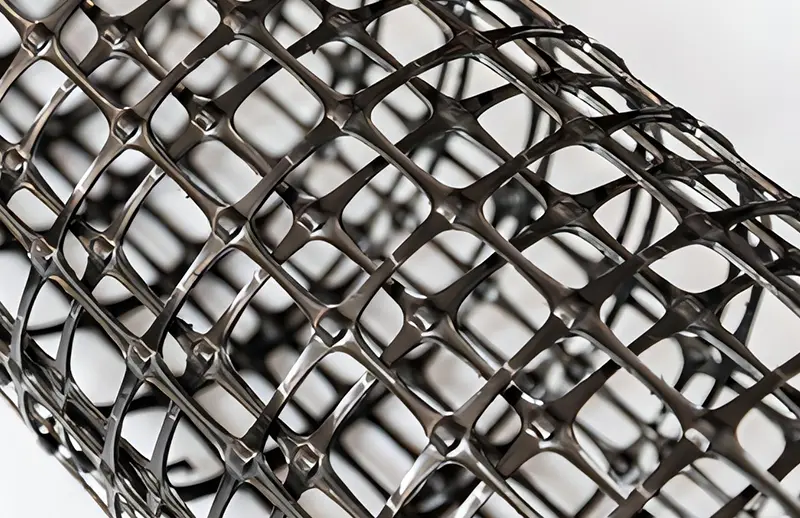

biaxial geogrid suppliers

biaxial geogrid suppliers

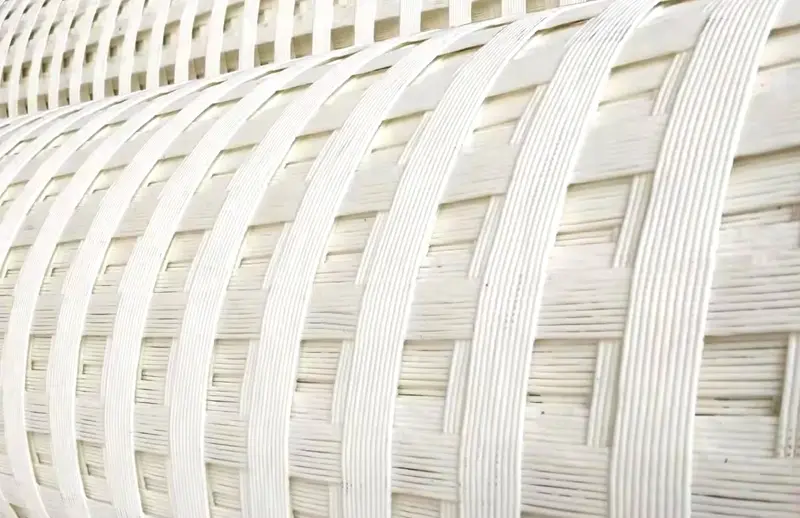

biaxial geogrid suppliers

biaxial geogrid suppliers

Biaxial Geogrid Suppliers—Biaxial Geogrid’s Feature

Durability

This can be attributed to their ability to resist corrosive chemicals which may lead to biological degradation.In the same way,Plastic geogrid is also resistant to moisture as well as UV rays since they maintain their structural status during such harsh environmental conditions.

Cost-effective

As opposed to other types of geogrid, plastic geogrid are a relatively cheaper option. This is due to low costs of production as well as distribution. Like wise, they are easy to work with thus making them to be easily installed as compared to other types of geogrid.

High Tensile Strength

They can withstand high pressure and loads since the pressure is evenly distributed throughout the material.Consequently,they are suitable for stabilizing soils specifically improving the bearing capacity of soils.

EROSION RESISTANCE

Compared to other types of geogrid, this type of geogrid is usually resistant to rust and corrosion. For example, geogrid made of metal and other related materials are highly likely to be affected by rust since they react in the presence of oxygen and moisture to form rust.

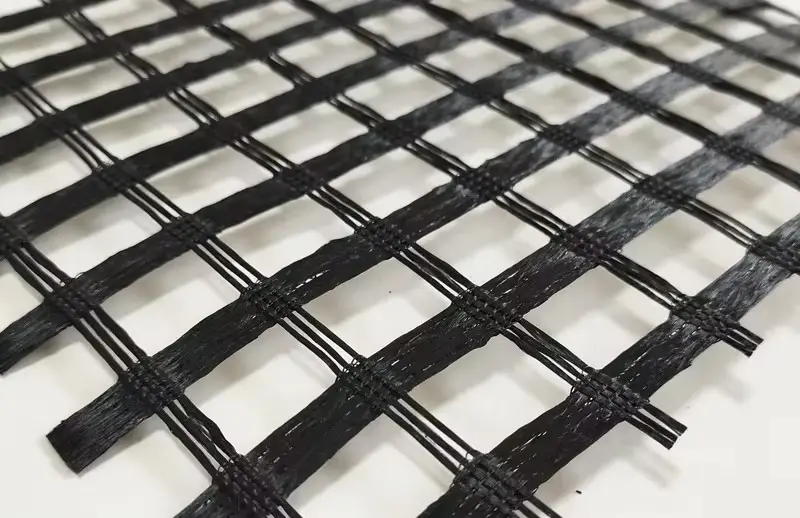

biaxial geogrid suppliers

biaxial geogrid suppliers