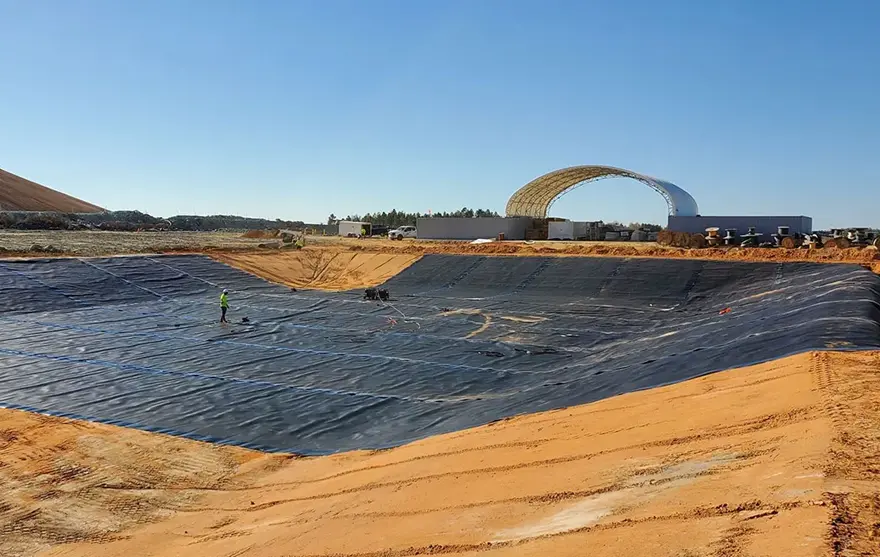

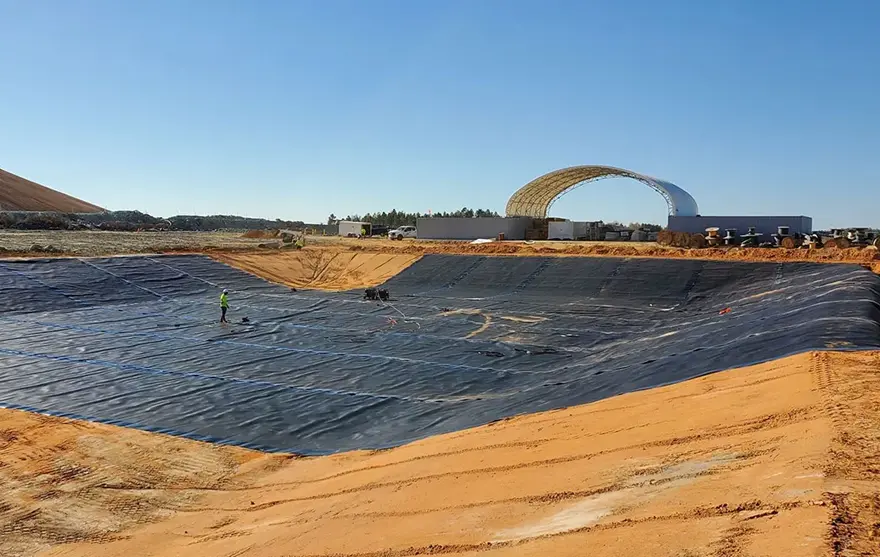

Composite geotextile is also called composite geomembrane and two cloth and one film or one cloth and one film. When laying composite geotextiles, it must be laid from the bottom up. The flatness between the film and the film and between the film and the substrate, but it is not suitable to stretch the film too tightly, usually slightly loose, and prevent air bubbles from remaining at the bottom of the impermeable film. Geomembranes are relatively thin and lightweight. It is easy to blow away if it is not placed before the maintenance layer. In order to spread the impermeable geomembrane, the area should not be too large. The best side of the film covers the soil retention layer. According to the data provided by the manufacturer, the width of the composite geomembrane is 1.0~10m, and the discussed material can be reduced according to the actual situation. Methods of hot-melting, gluing, and lapping are discussed. The seam width is 50~10 cm. If the geomembrane is punctured or torn, the geomembrane adhesive must be applied three times the damaged area.

Construction plan:

The geotextile acts as a protective layer of the membrane to protect the impermeable layer from damage. In order to reduce ultraviolet radiation and increase anti-aging performance, it is best to use the embedded method to lay.

1. During construction, the base surface should be leveled first with sand or clay with a small material diameter, and then laid. Don’t stretch it too tightly, the two ends are buried in the soil in a corrugated shape, and finally use fine sand or clay to lay a transition layer of about 10cm. Build a 20-30cm block stone (or concrete prefabricated block) as an anti-scour protective layer.

2. During construction, try to avoid stones falling directly on the composite membrane. It is best to construct the protective layer while laying the membrane. It should be connected with the surrounding structures with expansion bolts and steel plate bead anchorage, and the connection part should be painted with emulsified asphalt (thickness 2mm) to prevent leakage.

Construction Notes:

(1) The use must be embedded: the covering thickness should not be less than 30cm. Widely used in reservoir anti-seepage engineering

(2) The repair anti-seepage system should consist of cushion layer, anti-seepage layer, transition layer and protective layer.

(3) The soil body should be solid to avoid uneven subsidence and cracks, and the turf and tree roots within the anti-seepage range should be removed. Sand or clay with small particle size is laid on the contact surface with the membrane as a protective layer.

Composite geotextile features:

High physical and mechanical properties such as tensile, tear resistance, and bursting, the product has the characteristics of high strength, good elongation, large deformation modulus, acid and alkali resistance, corrosion resistance, aging resistance, and good impermeability. It can meet the needs of water conservancy (artificial lake), municipal administration, construction, transportation, subway, tunnel, breeding (lotus pond), and water canal. Anti-seepage, isolation, reinforcement, anti-crack reinforcement and other civil engineering needs in engineering construction. Due to the selection of polymer materials and the addition of anti-aging agents in the production process, it can be used in unconventional temperature environments.